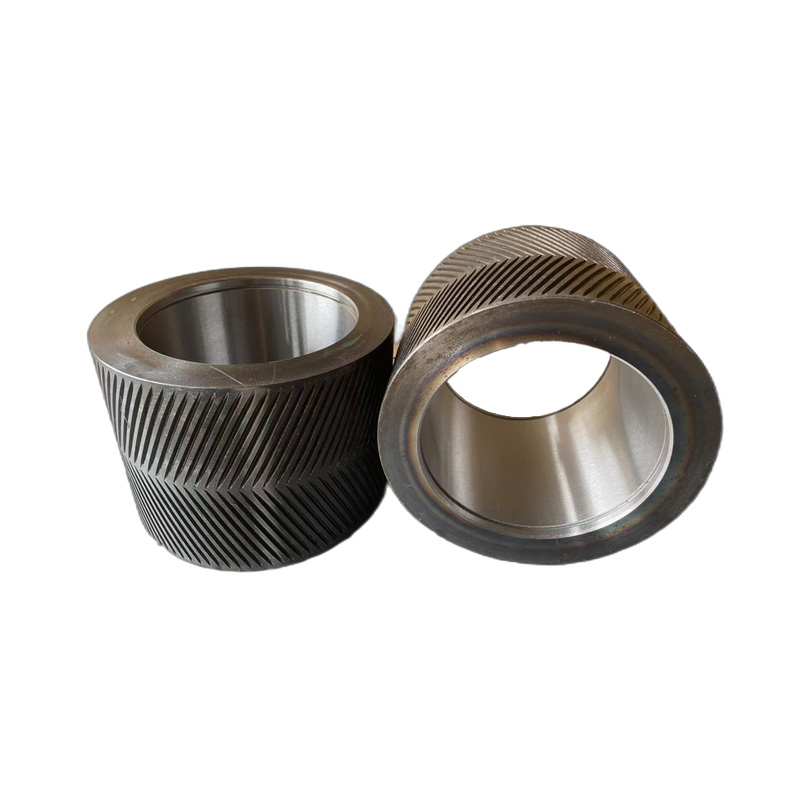

Y Model Teeth Roller Shell

A pellet mill roller shell is a cylindrical part of a pellet mill for compressing and compacting biomass materials into pellets. It usually consists of two or three rollers that rotate to press the biomass material against the die cavity in order to form small, hard pellets.

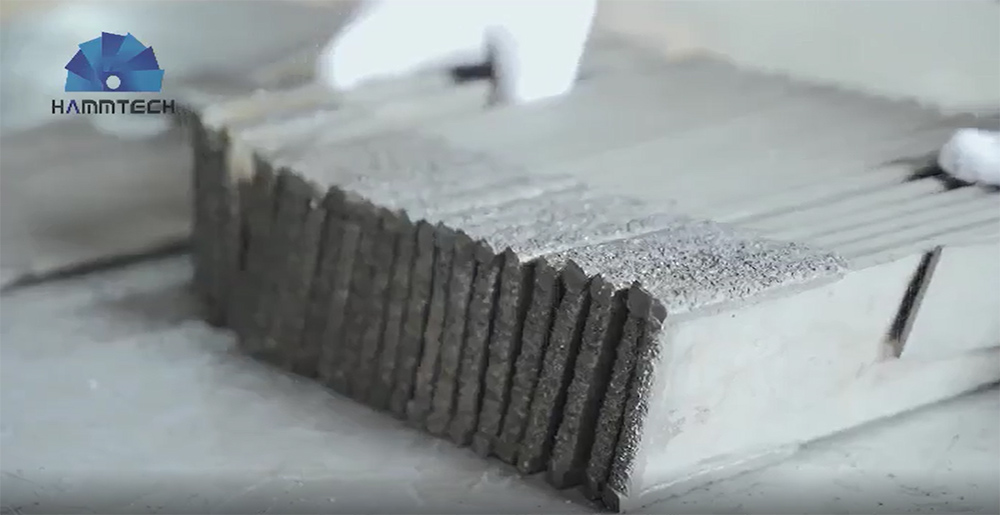

The surface of the roller shell may be smooth or grooved, depending on the specific application, to help improve the quality and uniformity of the pellets.

What material is the pellet mill roller shell generally made of? At present, there are mainly three kinds of materials used in the world: 20MnCr5 (alloy steel), GCr15 (bearing steel), and C50 (carbon steel).

1. 20MnCr5 is an alloy structural steel, carburized steel, with high strength and toughness, and good hardenability. Small quenching deformation, good low-temperature toughness, good machinability; but low welding performance. It is generally used after carburizing and quenching or tempering. The depth of the unobstructed carburized layer is 0.8-1.2mm. It is characterized by replacing bearing steel and is used in feed machines, which can play a very good role.

2. GCr15, also known as bearing steel, is the most commonly used high-chromium bearing steel with high hardenability. After quenching and tempering, it can obtain high and uniform hardness, good wear resistance, and high contact fatigue performance. The hardness is above HRC60, so the price is relatively high.

3. C50 belongs to high-quality medium-carbon alloy steel, which is easy to process and has good hardenability. It is suitable for manufacturing mold elements with high wear resistance requirements, large dynamic loads, and impact.

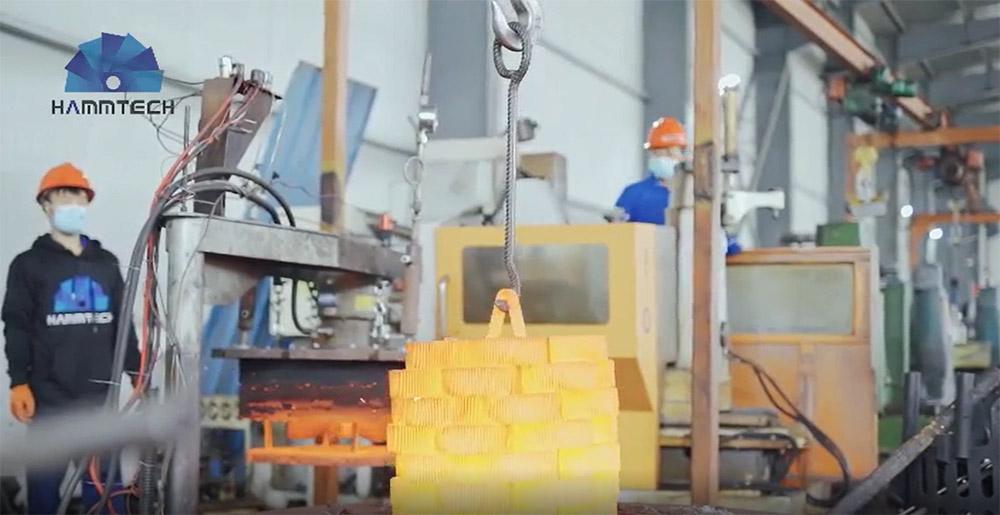

Changzhou Hammermill Machinery Technology Co., Ltd has been focusing on the production and development of hammer mills, feed pellet mills, sawdust granulators, biomass granulators, straw granulators, etc. We can provide customers with a series of complete sets of equipment and projects such as biomass slicing, crushing, drying, molding, cooling, packaging, etc.