Tungsten Carbide Sawdust Hammer Blade

◎ Wide applications

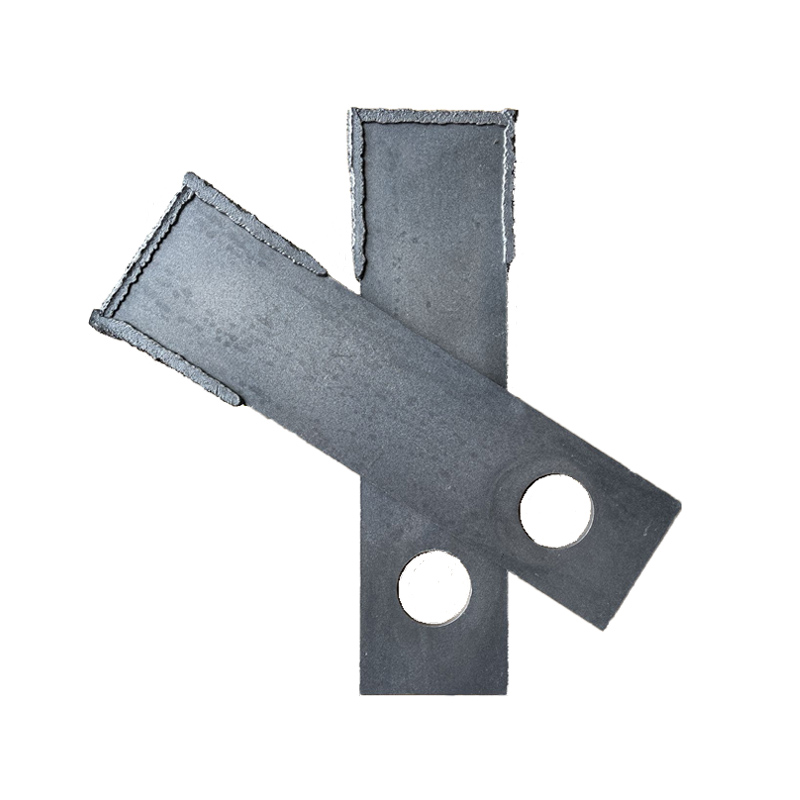

Hammer blades are also called swing blades. They are mainly applicable to various jaw crushers, straw crushers, wood crushers, sawdust crushers, dryer machines, charcoal machines, etc.

◎ Working principle

A group of hammer blades rotate through power transmission, and after reaching a certain speed, the feed material will be broken (big and small), and the crushed material will be discharged out of the machine through the holes of the screen under the action of the fan, so it is called hammermill.

1. Shape: single head single hole

2. Size: various sizes, customized

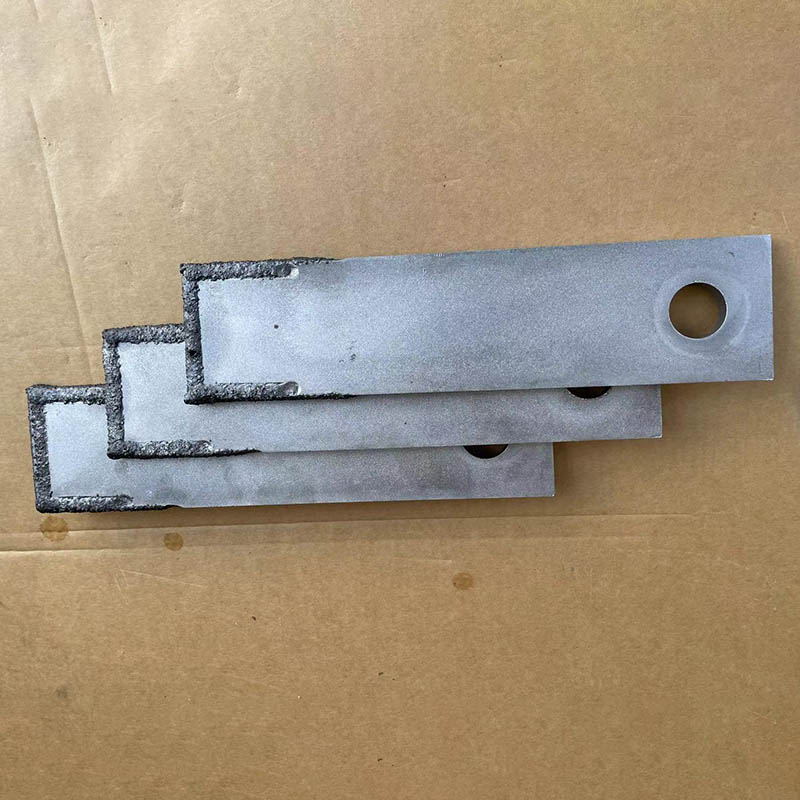

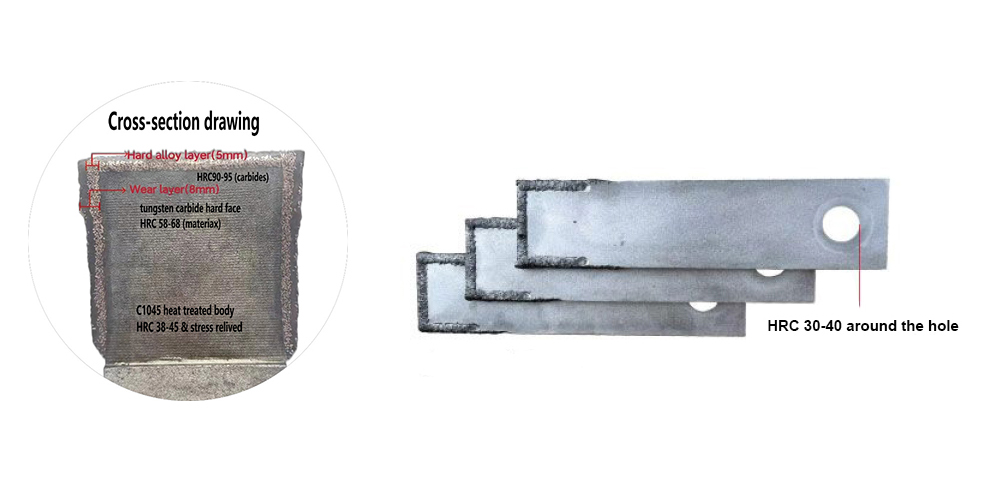

3. Material: high-quality alloy steel, wear-resistant steel

4. Hardness: HRC90-95 (carbides); tungsten carbide hard face – HRC 58-68 (materiax); C1045 heat treated body – HRC 38-45 & stress relived; around the hole: hrc30-40.

The thickness of the tungsten carbide layer is the same as that of the hammer blade body. It not only maintains the sharpness of hammer blade cutting but also enhances the abrasion resistance of the hammer blade.

◎ Forging

Carefully select and purchase steel. After heating at a high temperature, the workpiece can be forged repeatedly by air hammer. Better quality density, better quality density

◎ Finish machining

Various CNC finishing machines are used to ensure accuracy and efficiency. Stable processing quality. Fixed, good quality, high repeatability

◎ Heat treatment

Vacuum quenching furnace with large diameter is selected for heat treatment, with uniform heat treatment, high hardness and toughness. Strong and not easy to break.

◎ Fine grinding

Precision grinding machine is used for cutting, with high sharpness, good parallelism, long service time, good effect of finished products and neat specifications.