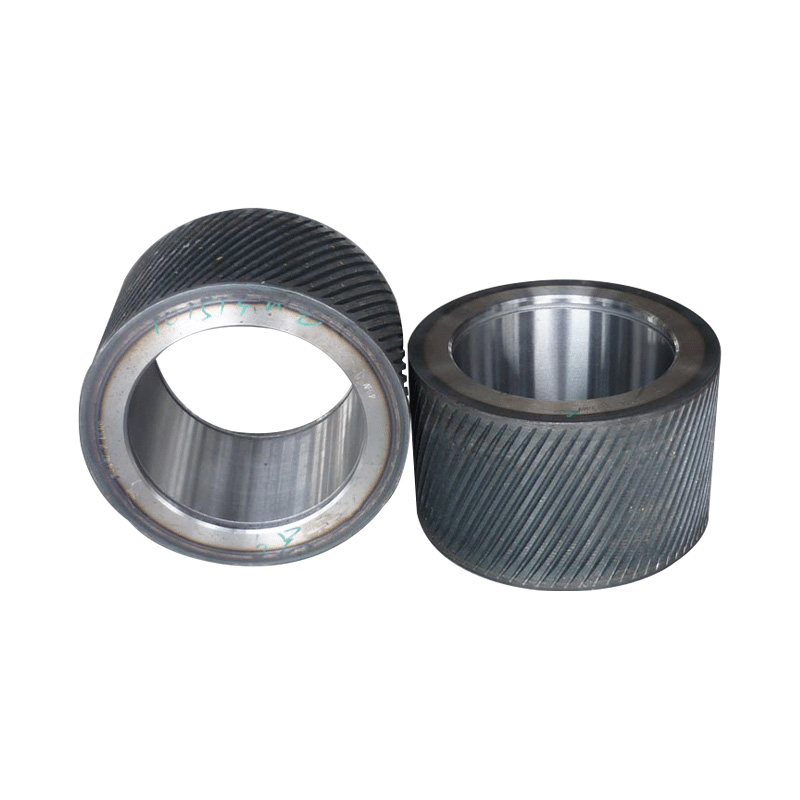

Tungsten Carbide Roller Shell

Tungsten carbide is a hard and wear-resistant material, making roller shells made from it highly durable and able to withstand heavy use and abrasion. Tungsten carbide roller shells have excellent performance in terms of reducing wear and tear, providing consistent and high-quality output, and minimizing downtime and maintenance costs. Although tungsten carbide roller shells can be more expensive initially, they are more cost-effective in the long run due to their durability and performance, which reduces the need for frequent replacements and repairs. Thus, they can improve the efficiency of the production process by reducing waste and increasing productivity, resulting in higher output and greater profitability.

Tungsten carbide roller shells are an excellent choice for pellet mills.

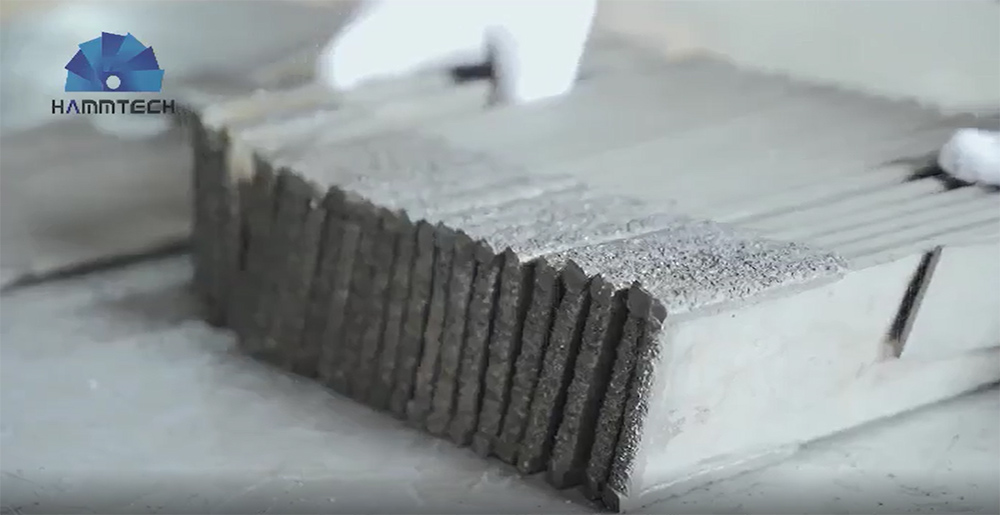

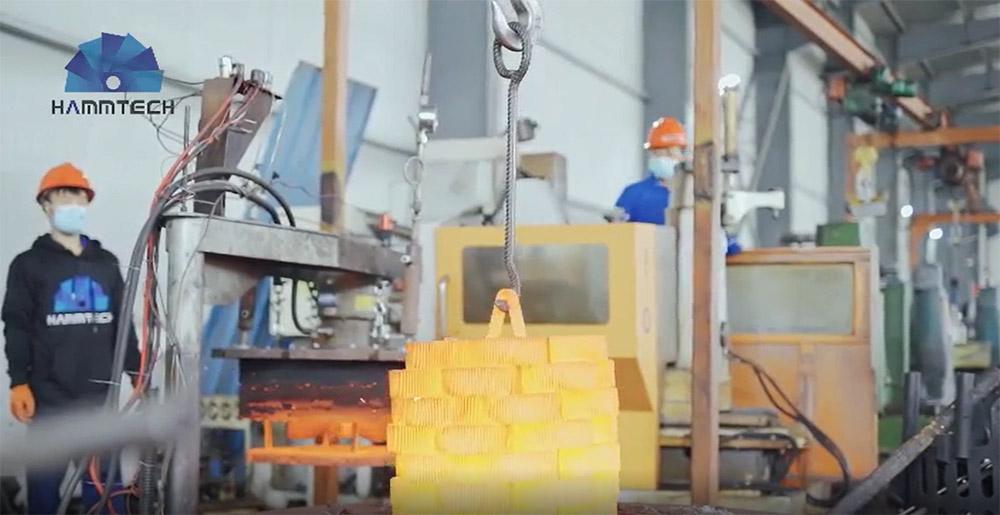

Our company focuses on the customization of roller shells, strictly according to customer drawings or samples, to produce various types of roller shells. We use high-quality steel to ensure the hardness and wear resistance of the pellet mill roller shells. The exquisite high-temperature quenching process significantly extends the service life and is twice as long as ordinary roller shells in the market. Our products are suitable for a variety of raw material pellet production, wood chip pellets, feed pellets, and bio-energy pellets.

With a strong sales and service team, we provide pre-sales consultation, solution design, and product customization services to customers worldwide.