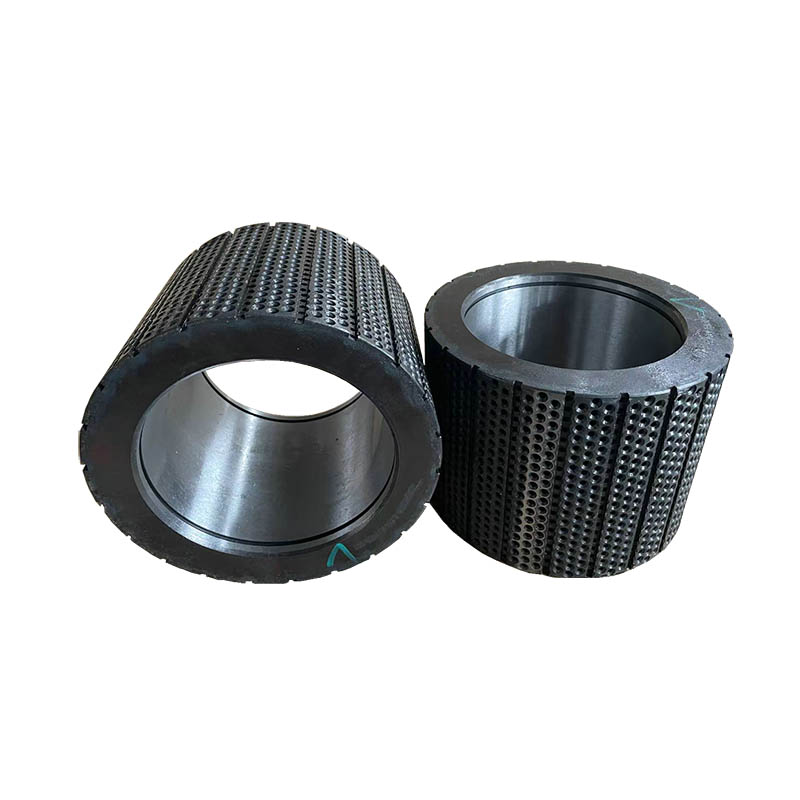

Straight Teeth Roller Shell

The pellet mill roller shell is a kind of wear parts that needs to be replaced if necessary. In order to prolong its service life, we should follow the steps below to learn how to maintain it.

1. Clean the roller shell regularly with a brush or compressed air to remove dust and debris.

2. Inspect the roller shell for any signs of wear or damage. If there is any damage, replace the roller shell as soon as possible.

3. Proper lubrication is critical for the smooth operation of the pellet mill and the roller shell. Lubricate the roller shell and the bearings with the appropriate lubricant, according to the manufacturer's recommendations.

4. Check the tightness of the roller shell regularly. If it is loose, adjust it to the correct position.

5. The temperature of the pellet mill should be monitored and controlled to prevent overheating, which can damage the roller shell. Follow the manufacturer's recommendations for temperature control.

6. Select the appropriate material for the roller shell based on the type of material being processed. For example, harder materials require more durable roller shells.

7. Proper operator training is essential for the safe and effective operation of the pellet mill. Ensure that operators are trained on the proper operation and maintenance procedures.

1. Avoid overloading the pellet mill. Overloading can cause excessive wear and tear on the roller shell, leading to its premature failure.

2. Never use a damaged roller shell. It can cause damage to the pellet mill and lead to unsafe conditions.

3. Ensure that the pellet mill is turned off before any maintenance or cleaning.

4. Always wear appropriate protective equipment such as gloves, goggles, and ear protection to avoid any accidents.

5. Always refer to the manufacturer's manual for specific instructions on maintenance and proper use of the pellet mill.