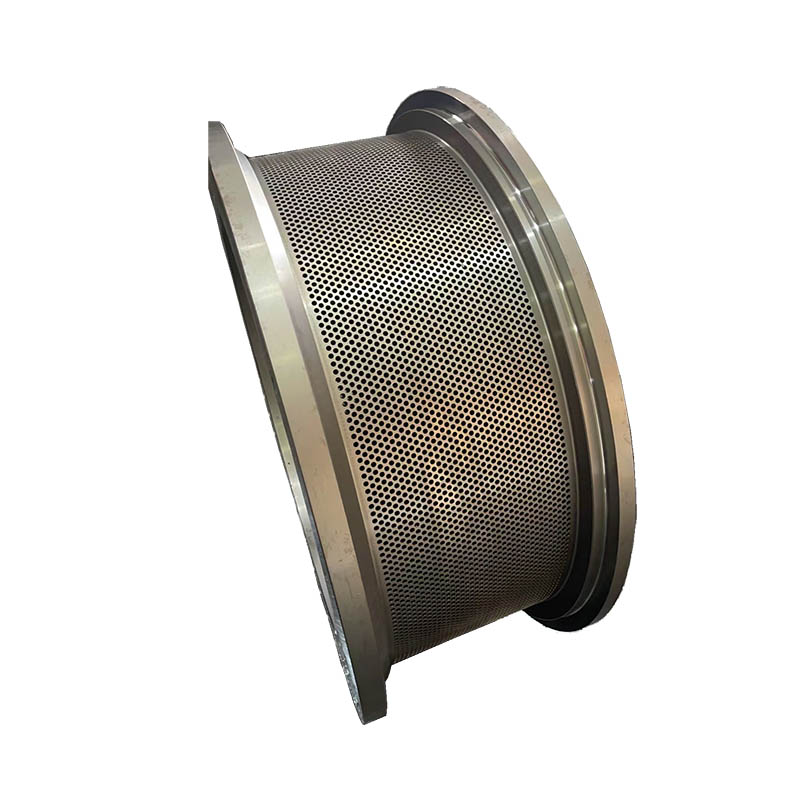

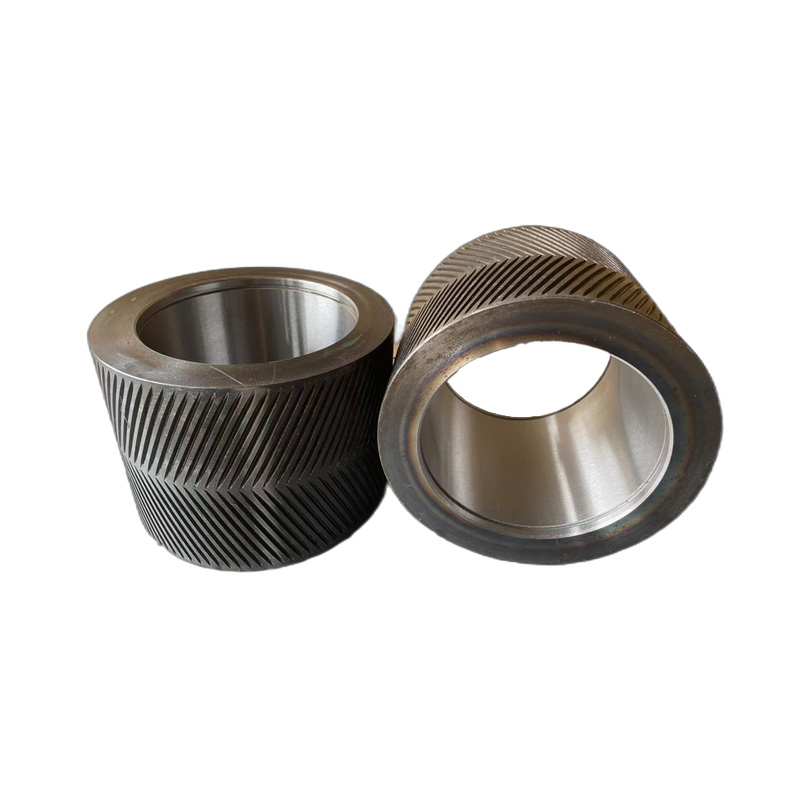

Stainless Steel Roller Shell With Open Ends

● Each pellet mill roll shell is manufactured with extreme precision using the highest quality stainless steel.

● Our roller shells are highly resistant to wear, breakage, and corrosion.

| Product | Roller shell |

| Material | Stainless steel |

| Process | Lathing, milling, drilling |

| Size | As per customer drawing and requirements |

| Surface Hardness | 58-60HRC |

| Machinery Test Report | Provided |

| Package | According to customers’ requests |

| Machinery Test Report | Provided |

| Features | 1. Strong, durable 2. Corrosion-resistant 3. Low coefficient of friction 4. Low maintenance requirements |

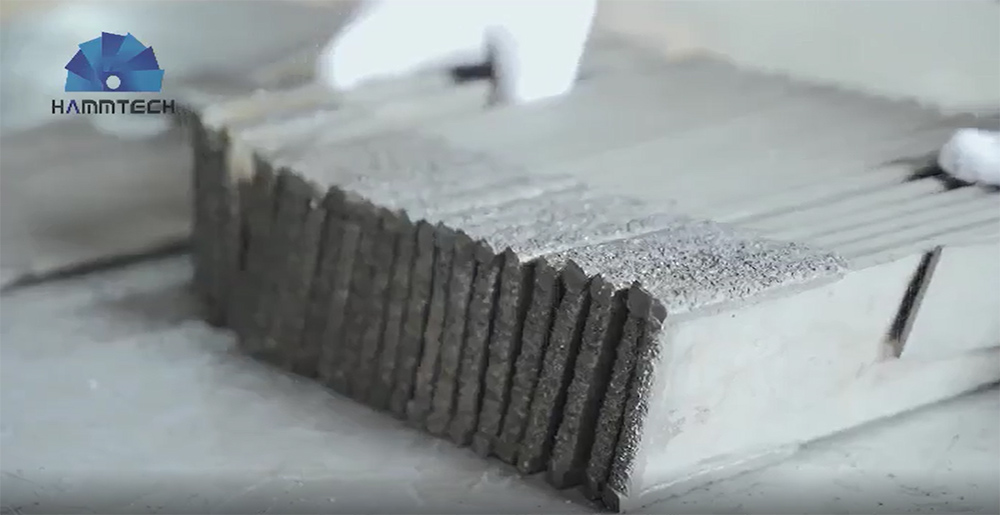

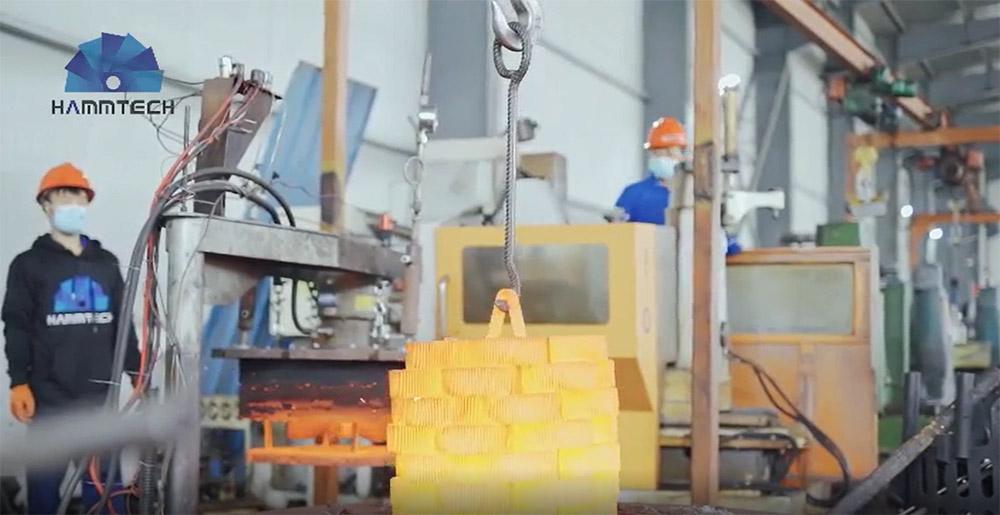

The roller shell works under extremely harsh conditions. Huge forces are transmitted from the die surface through the bearings to the roller support shaft. Friction causes fatigue cracks to appear on the surface. After a certain depth of fatigue cracking has occurred during production, the service life of the shell is extended accordingly.

The life span of the roller shell is critical, as the frequent replacement of the roller shell can also damage the ring die. Therefore, when purchasing pelletizing equipment, the material of the roll shell should also be taken into consideration. Chrome steel alloy material is desirable because it has good fatigue resistance and is suitable for the requirements of operating in harsh environments.

A good roller shell is not only made of good material but also matches the excellent properties of its dies. Each die and roller assembly stay together as a unit, extending the life of the die and roller and making it easy to store and convert.

We can supply complete sets of accessories for pellet mill, such as pulverizer hammer blades, granulator ring dies, flat dies, granulator grinding discs, granulator roller shells, gears (large/small), bearings, connecting hollow shafts, safety pin assemblies, couplings, gear shafts, roller shell assemblies, various knives, various scrapers.