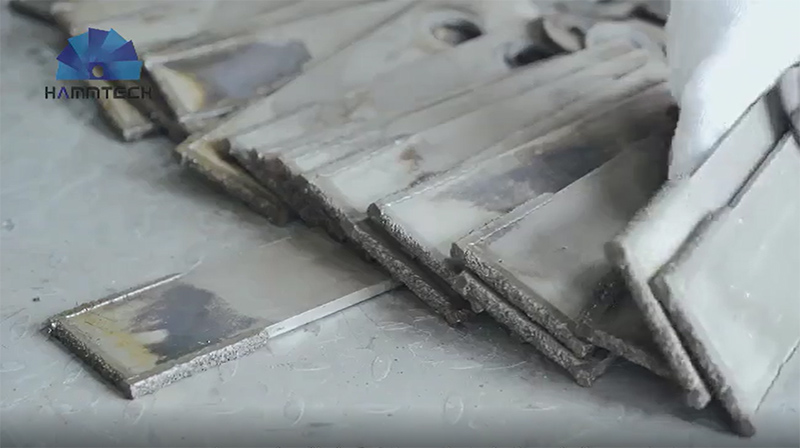

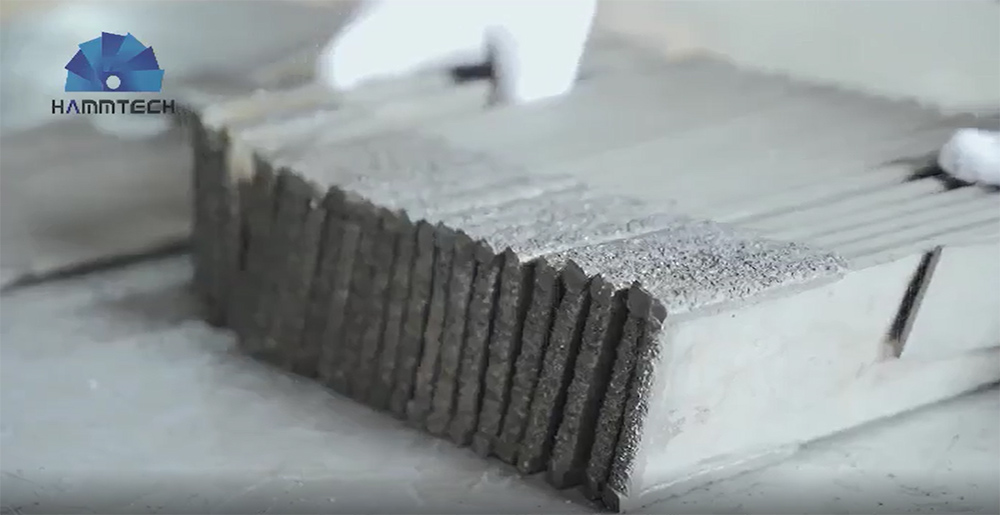

Single Hole Smooth Plate Hammer Blade

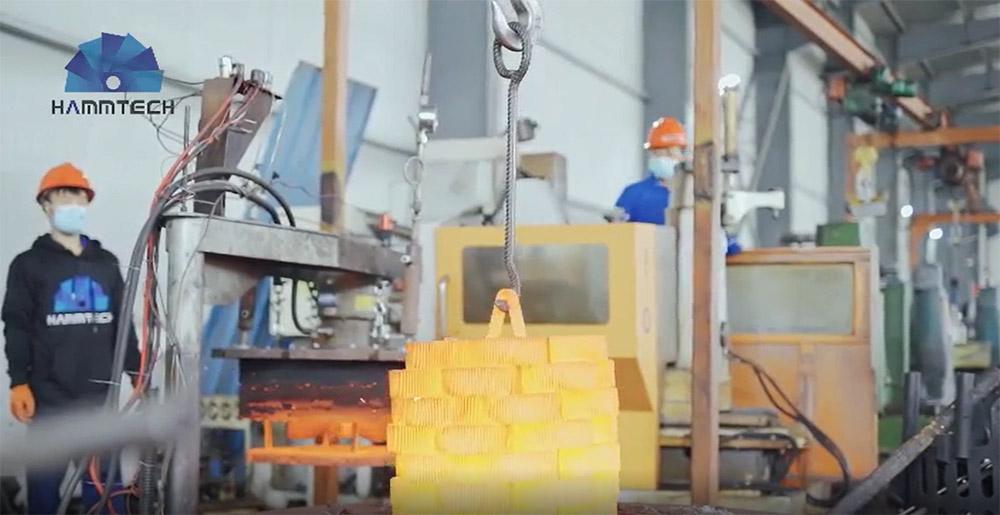

A hammer mill blade, also known as a beater, is a component of a hammer mill machine that is used to crush or shred materials such as wood, agricultural produce, and other raw materials into smaller pieces. It is typically made from hardened steel, and it can be shaped in a variety of ways depending on the intended application of the hammer mill. Some blades may have a flat surface, while others may have a curved or angled shape to provide different levels of impact and crushing force.

They work by striking the material being processed with a high-speed rotating rotor that is equipped with several hammer blades or beaters. As the rotor rotates, the blades or beaters repeatedly impact the material, breaking it down into smaller pieces. The size and shape of the blades and screen openings determine the size and consistency of the material produced.

To maintain the blades of a hammer mill, you should regularly inspect them for signs of wear and damage. If you notice any cracks, chips, or dullness, you should replace the blades immediately to ensure optimal performance. You should also lubricate the blades and other moving parts regularly to prevent friction and wear.

When using a hammer mill blade, there are several cautions you should pay attention to. Firstly, make sure to use the machine only for its intended purpose and within its specified capacity to avoid overloading it. Additionally, always wear appropriate safety gear such as gloves, eye protection, and earplugs to prevent injury from flying debris or excessive noise. Finally, never put your hands or other body parts near the blade while the machine is in operation to avoid getting caught in the rotating blades.