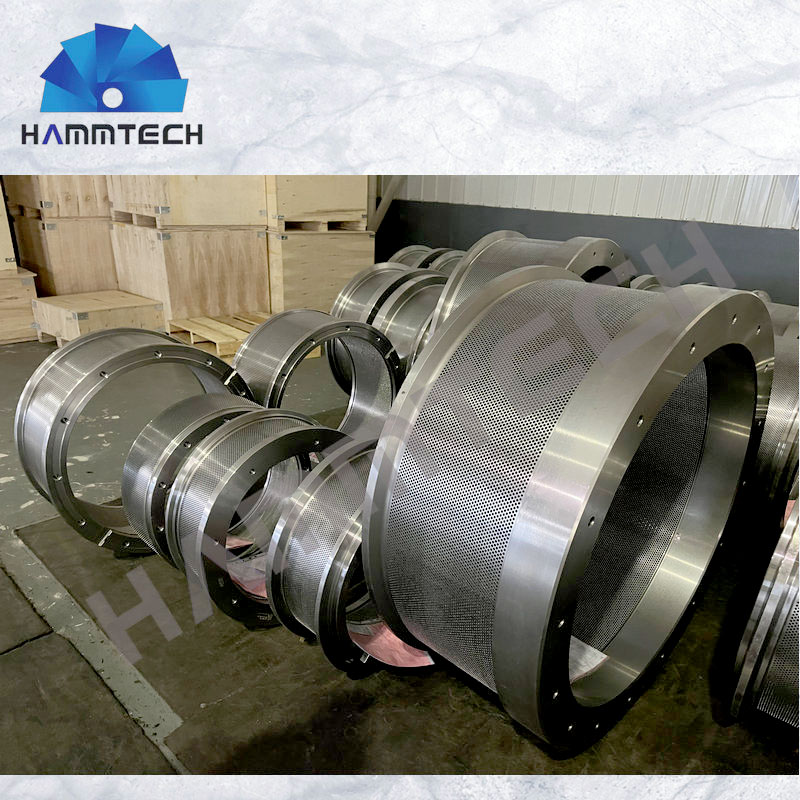

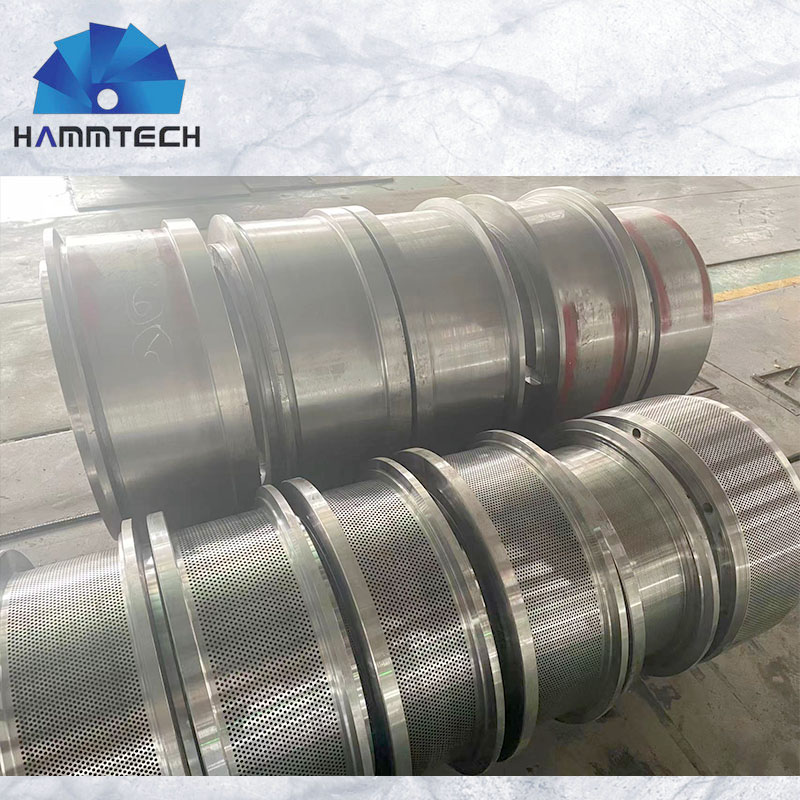

Shrimp Feed Pellet Mill Ring Die

The ring die is one of the core components of feed and biomass pellet mill. The quality of the ring die is related to the safe and smooth operation of feed production, directly related to the appearance and internal quality of feed, production efficiency and energy consumption, and is an important link in the production of feed enterprises.

We can provide different kinds of ring dies.

Zhengchang(SZLH/MZLH), Amandus Kahl, Muyang(MUZL), Yulong(XGJ), AWILA,PTN, Andritz Sprout, Matador, Paladin, Sogem, Van Arssen, Yemmak, Promill; etc. We can customize for you according to your drawing.

For CPM pellet mill: CPM2016, CPM3016, CPM3020, CPM3022, CPM7726, CPM7932, etc.

For Yulong pellet mill: XGJ560, XGJ720, XGJ850, XGJ920, XGJ1050, XGJ1250.

For Zhengchang pellet mill: SZLH250, SZLH300,SZLH320,SZLH350,SZLH400, SZLH420, SZLH508, SZLH678, SZLH768, etc.

For Muyang pellet mill: MUZL180, MUZL350, MUZL420, MUZL600, MUZL1200, MUZL610, MUZL1210, MUZL1610, MUZL2010.

MUZL350X, MUZL420X, MUZL600X, MUZL1200X(Especially for shrimp feed pellet, diameter: 1.2-2.5mm).

For Awalia pellet mill: Awalia 420, Awalia350, etc.

For Buhler pellet mill: Buhler304, Buhler420, Buhler520, Buhler660, Buhler900, etc.

For Kahl pellet mill(Flat die): 38-780, 37-850, 45-1250, etc.

In general, the higher the compression ratio, the higher the density of the finished pellet. However, this does not mean that the higher the compression ratio, the better the quality of the pellets. The compression ratio should be calculated according to the raw material and the type of feed used to make the pellets.

With years of experience in manufacturing and researching pellet dies, we provide some general data on ring die compression ratios for your reference. Buyers can customize the ring dies with different hole diameters and compression ratios according to different situations and requirements.

|

FEED MODEL |

HOLE DIAMETER |

COMPRESSION RATIO |

|

POULTRY FEED |

2.5mm-4mm |

1:4-1:11 |

|

LIVESTOCK FEED |

2.5mm-4mm |

1:4-1:11 |

|

FISH FEED |

2.0mm-2.5mm |

1:12-1:14 |

|

SHRIMP FEED |

0.4mm-1.8mm |

1:18-1:25 |

|

BIOMASS WOOD |

6.0mm-8.0mm |

1:4.5-1:8 |

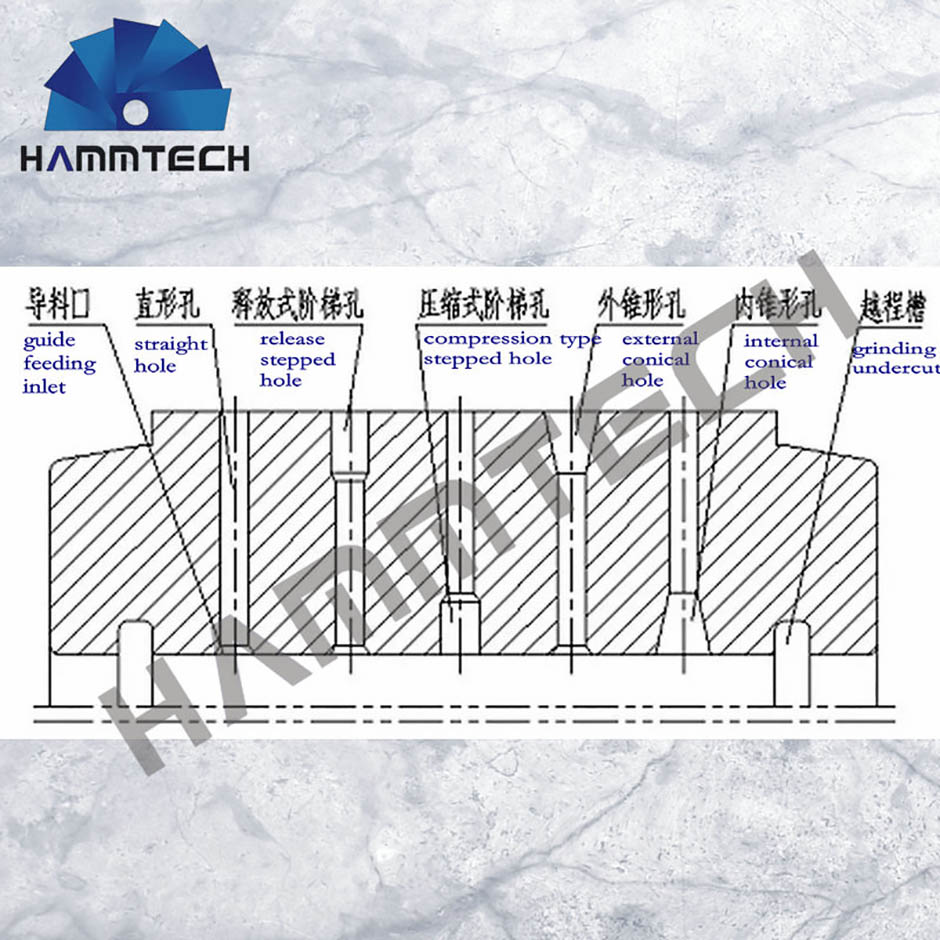

The most common structure of die hole are straight hole; release stepped hole; external conical hole and internal conical hole, etc. Different die holes structure are suitable for different raw material and feed formula for making pellets.