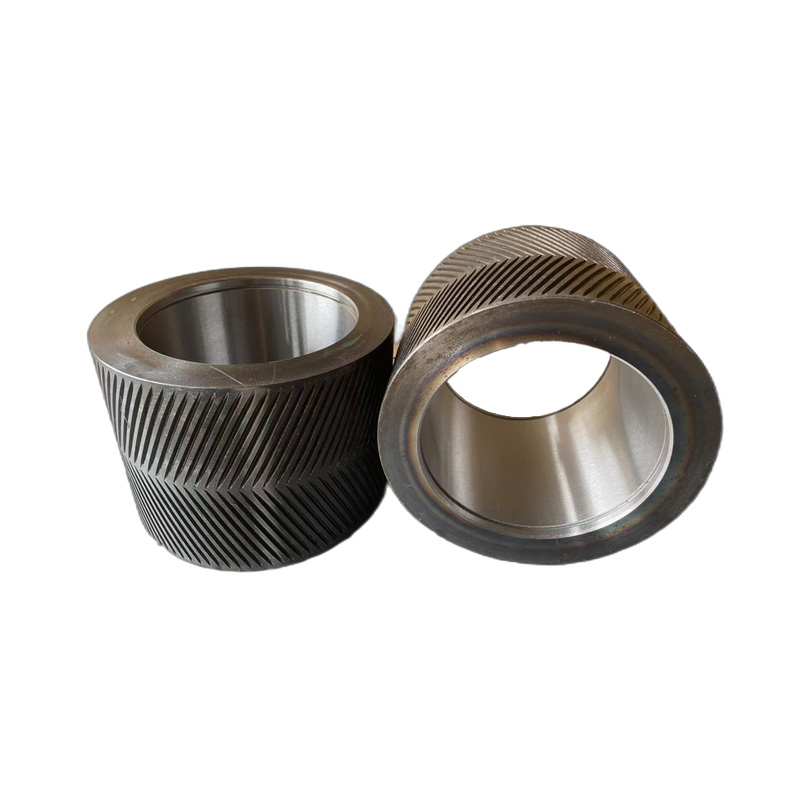

Roller Shell Shaft for Pelletizer Machine

A roller shell shaft is a component of a roller shell, which is a cylindrical part used in various industrial applications, such as material handling and conveyors. The roller shell shaft is the central axis around which the roller shell rotates. It is typically made of strong and durable materials, such as steel or aluminum, to withstand the forces exerted on the roller shell during operation. The size and specifications of the roller shell shaft depend on the specific application and the load that it is required to support.

The characteristics of a roller shell shaft depend on the specific application, but some common features include:

1. Strength: The roller shell shaft must be strong enough to support the load applied to the roller shell and withstand the forces exerted during operation.

2. Durability: The roller shell shaft must be made of materials that can withstand wear and tear over time and resist corrosion.

3. Precision: The roller shell shaft must be manufactured with precision to ensure a smooth and consistent operation of the roller shell.

4. Surface Finish: The surface finish of the roller shell shaft can impact its performance. A smooth and polished surface reduces friction and increases the longevity of the roller shell.

5. Size: The size of the roller shell shaft depends on the specific application and the load it is required to support.

6. Material: The roller shell shaft can be made of various materials, including steel, aluminum, or other metals, based on the specific requirements of the application.

7. Tolerance: The roller shell shaft must be manufactured to strict tolerances to ensure proper fit and function within the roller shell assembly.

We provide various roller shell shafts and sleeves for more than 90% of the world's different types of pellet mills. All roller shell shafts are made of high-quality alloy steel (42CrMo) and undergo special heat treatment to achieve fine durability.