Roller Shell Shaft Bearing Spare Parts

A pellet mill roller shaft is a device used in the production of pellets from various types of materials. It functions as a spinning roller with grooves that run along its surface to crush the raw material into small, granulated pieces. The roller shaft helps the pellet mill to create pellets with the desired shape, size, and quality.

We supply a wide range of roller shell shafts and sleeves for more than 90% of the different types of pellet machines in the world. All roller shell shafts are made of high quality alloy steel (42CrMo) and are specially heat treated for excellent durability.

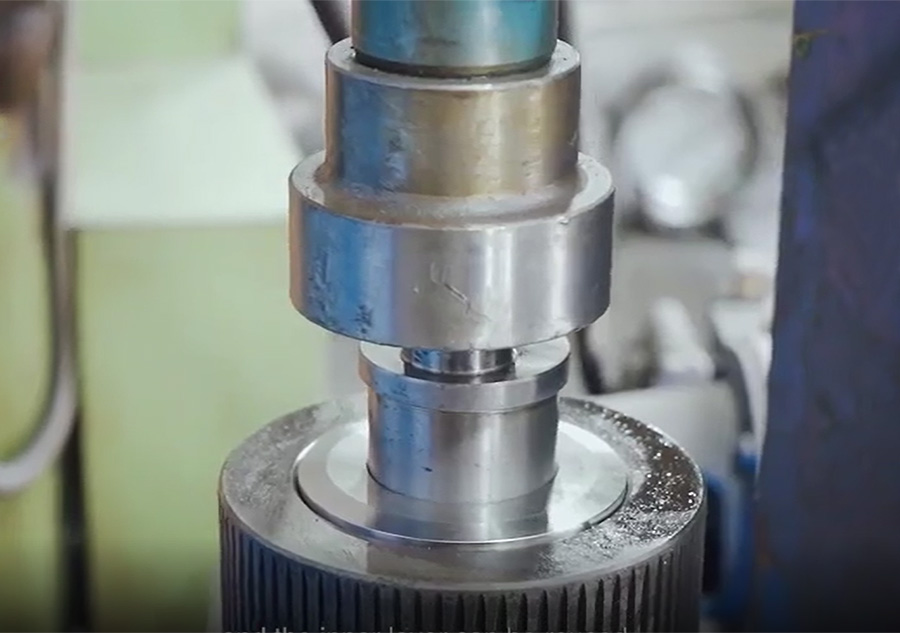

The process of installing a shaft into a roller shell involves the following steps:

1. Clean the parts: Clean the shaft and the inside of the roller shell to remove any dirt, rust, or debris.

2. Measure the parts: Measure the diameter of the shaft and the inside diameter of the roller shell to ensure a proper fit.

3. Align the parts: Align the shaft and the roller shell so that the ends of the shaft are centered with the ends of the roller shell.

4. Apply lubricant: Apply a small amount of lubricant, such as grease, to the inside of the roller shell to reduce friction during assembly.

5. Insert the shaft: Slowly and evenly insert the shaft into the roller shell, making sure that it is properly aligned. If necessary, gently tap the end of the shaft with a soft-faced hammer to seat it into place.

6. Secure the shaft: Secure the shaft in place by using set screws, locking collars, or other suitable methods.

7. Test the assembly: Test the assembly by rotating the roller to ensure that it rotates smoothly and there is no binding or excessive play.

It is important to follow the manufacturer's recommendations for installing the shaft and roller shell to ensure proper fit, performance, and longevity.