Roller Shell Assembly for Pellet Machine

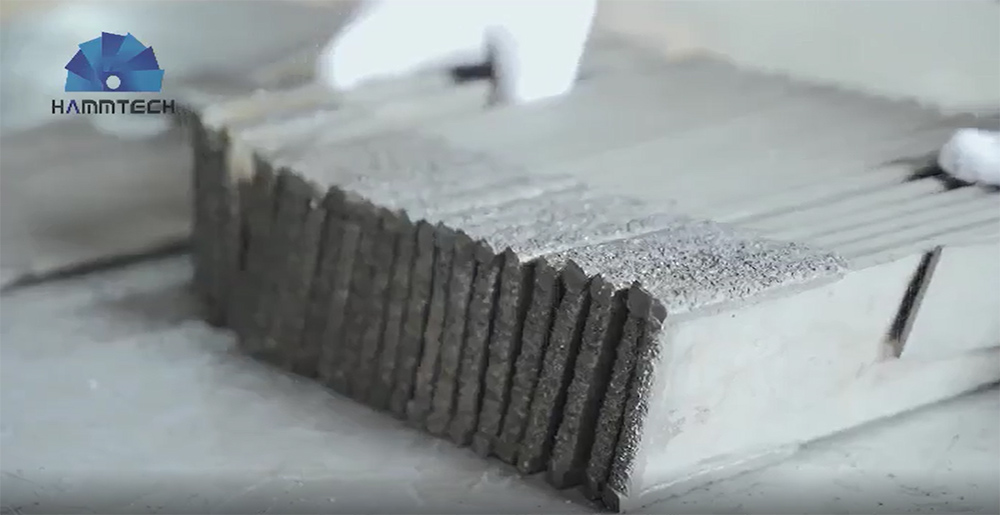

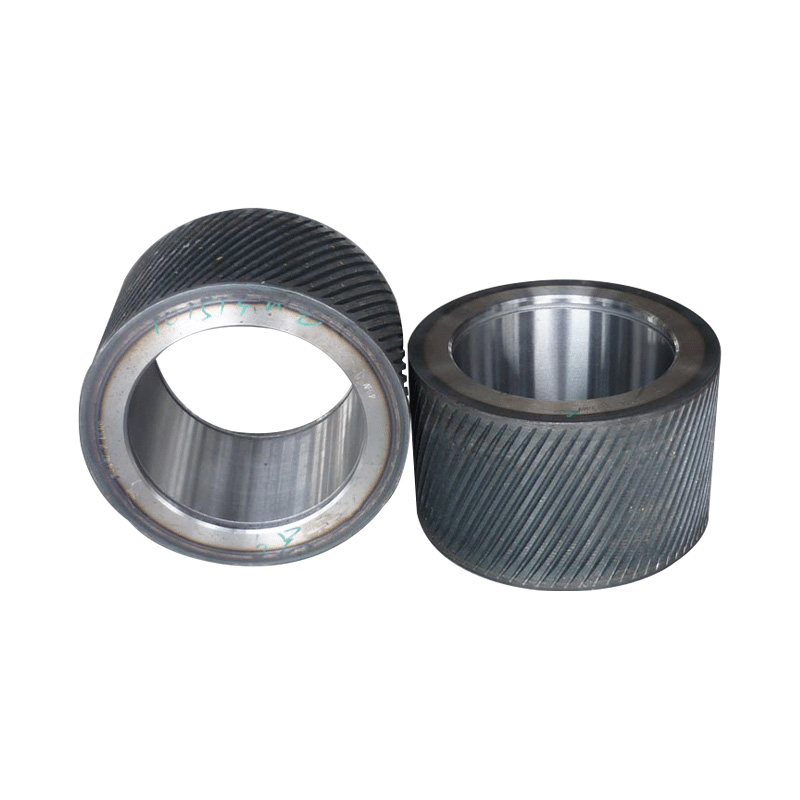

A pellet mill roller assembly is a component of a pellet mill machine used in the production of pelletized feed or biomass fuel. It consists of a pair of cylindrical rollers that rotate in opposite directions to compress and extrude the raw materials through a die to form pellets. The rollers are made from high-quality steel and are usually mounted on bearings that allow them to rotate freely. The central shaft is also made from steel and is designed to support the weight of the rollers and transmit power to them.

The quality of the pellet mill roller assembly directly affects the quality and productivity of the pellet mill. Thus, regular maintenance and replacement of worn parts are crucial to ensuring optimal performance and longevity of the pellet mill.

Product Features

● Wear resistance, corrosion resistance

● Fatigue resistance, impact resistance

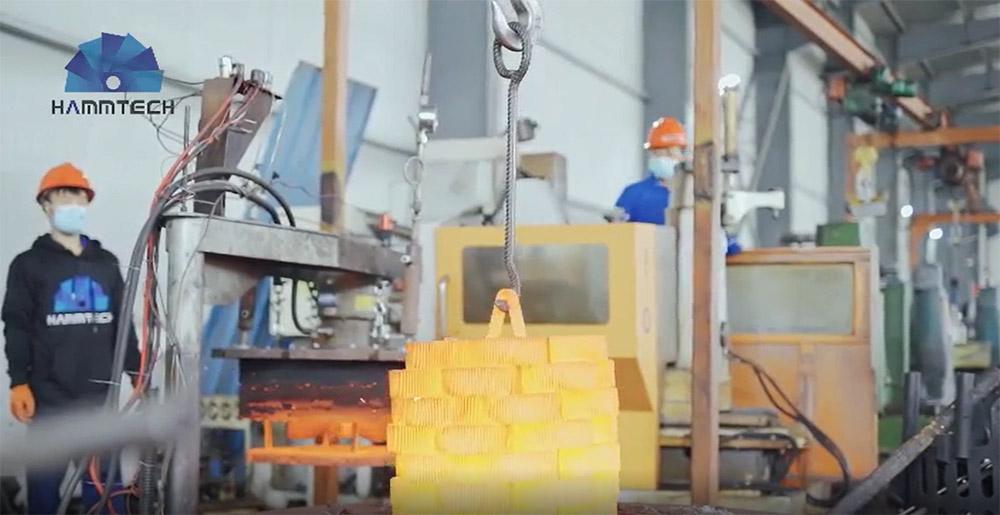

● Fully automatically controlled during the manufacturing process

● Suit for various kinds of pellet machines

● Meet with the industry standard

● According to customers' drawings

As the raw material enters the pellet mill, it is fed into the gap between the rollers and the die. The rollers rotate at high speed and exert pressure on the raw material, compressing it and forcing it through the die. The die is made from a series of small holes, which are sized to match the desired pellet diameter. As the material passes through the die, it is shaped into pellets and pushed out the other side with the aid of cutters located at the end of the die. The friction between the rollers and the raw materials creates heat and pressure, causing the material to soften and stick together. The pellets are then cooled and dried before being packaged for transport and sale.