Products

-

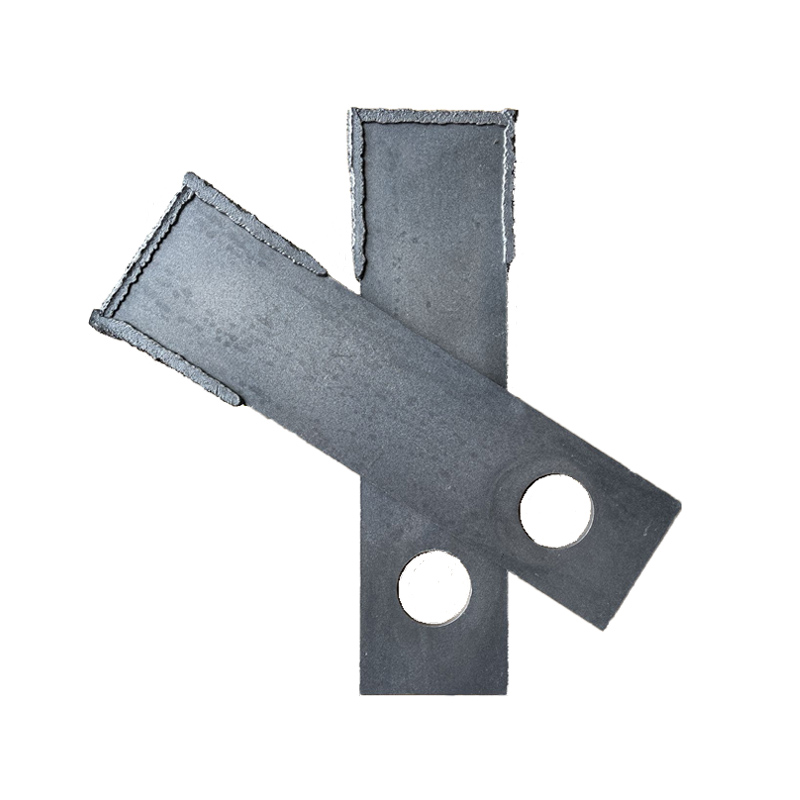

HMT Tungsten Carbide Overlay Welding Hammer Blade

4 unique advantages:

*Super wear-resistant *High crushing efficiency

*The wear-resistant layer does not fall off *The body of hammer blade does not break -

Flat Overlay Welding Hammer Blade With Tungsten Carbide

Our flat overlay welding hammer blade with tungsten carbide features with a wear-resistant layer on the surface which ensures strong adhesion without detachment. The layer’s ultra-high hardness ensures long service life, reducing replaccement frequency and maintenance cost.

-

Tungsten Carbide Overlay Welding Hammer Blade

We supply tungsten carbide overlay welding hammer blades with extremely high hardness, strong wear resistance, and long service life. They perform reliably in harsh environments and are perfect for heavy industries.

-

Application Particles of Tungsten Carbide Welding Technology in Shear Vulnerable Parts

Super wear-resistant, super impact resistant, sharp and secondary tearing.

-

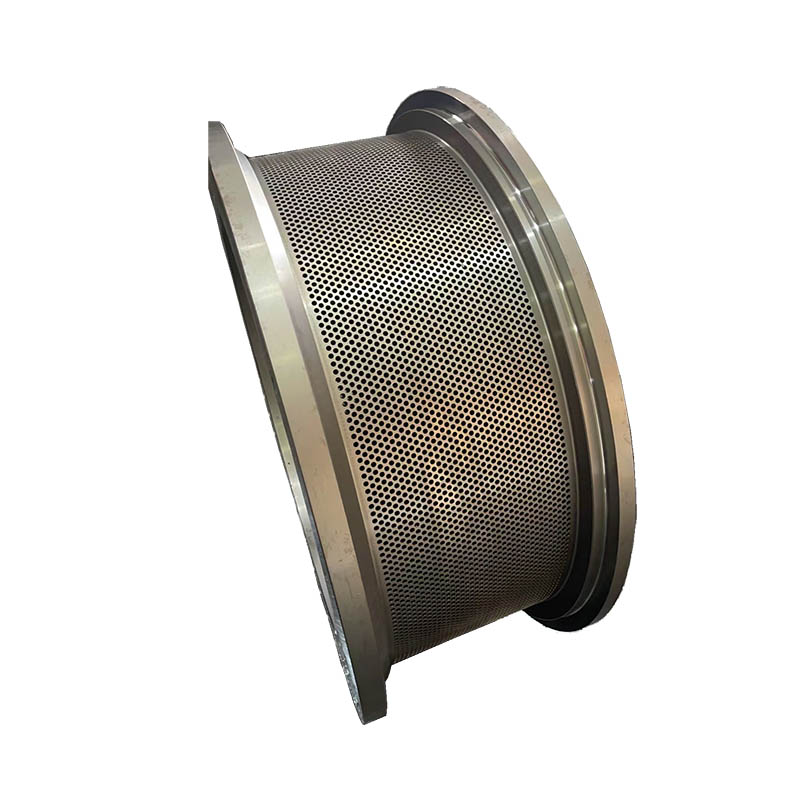

Ring Die

We can supply ring dies for all the main brands of pellet machine such as CPM, Buhler, CPP, and OGM. Customized dimensions and drawings of ring dies are welcome.

-

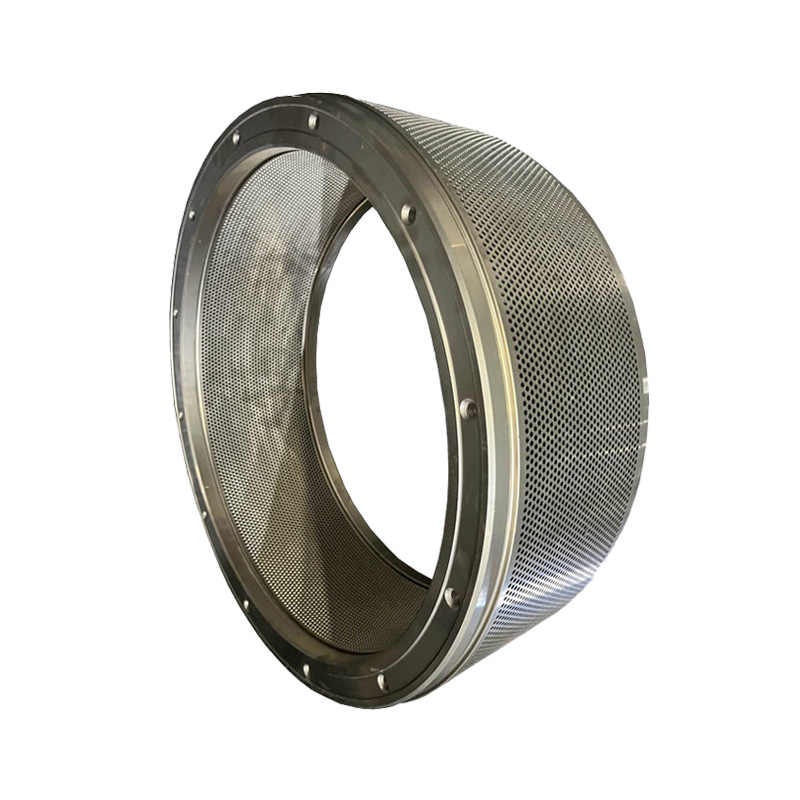

Crab Feed Pellet Mill Ring Die

The ring die has good tensile strength, good corrosion and impact resistance. The shape and depth of die hole and the hole-opening rate are guaranteed to meet the different requirements of aquafeed.

-

Fish Feed Pellet Mill Ring Die

The hole distribution of the ring die is uniform. Advanced vacuum heat treatment process, avoid the oxidation of die holes, effectively ensure the finish of die holes.

-

Poultry and Livestock Feed of Pellet Mill Ring Die

This pellet mill ring die is ideal for the pelleting of poultry and livestock feeds. It has a high yield and produces beautifully formed, high-density pellets.

-

Cattle and Sheep Feed Pellet Mill Ring Die

The ring die is made of a high chrome alloy, drilled with special deep-hole guns and heat-treated under vacuum.

-

Flat Die for Pellet Machine

HAMMTECH offers a wide range of flat dies with different sizes and parameters. Our flat die has good mechanical properties and long service life.

-

Tungsten Carbide Hammer Blade With Single Hole

Tungsten carbide hammer blades are often designed with anti-vibration features that help to reduce the amount of shock and vibration transferred to the user’s hand and arm during use.

-

Tungsten Carbide Hammer Blade With Double Holes

The hardness and density of tungsten carbide allows it to transmit more force to the object being struck, which can increase the impact force of the hammer blade.