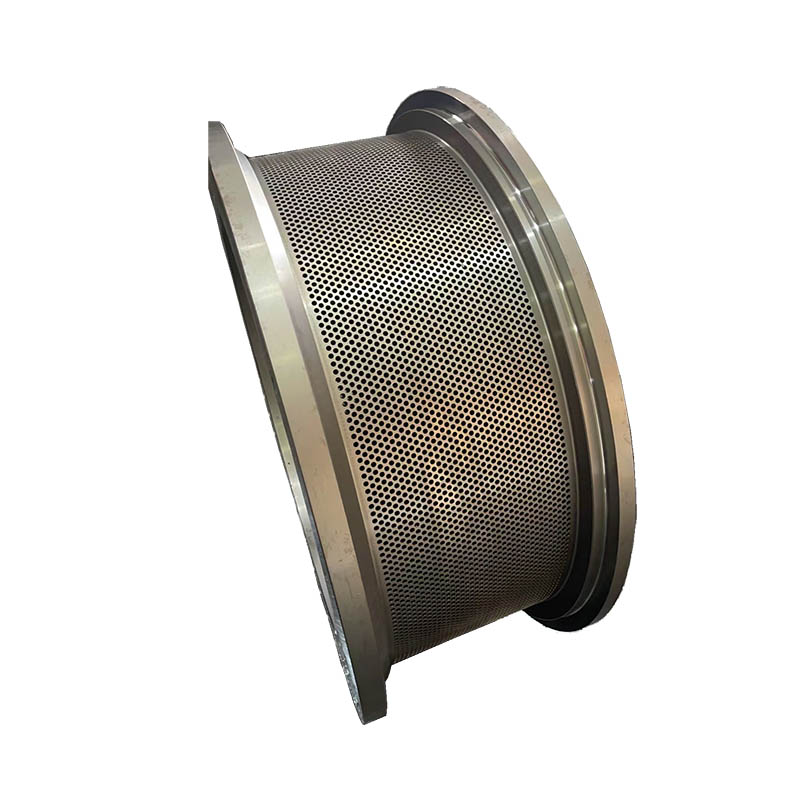

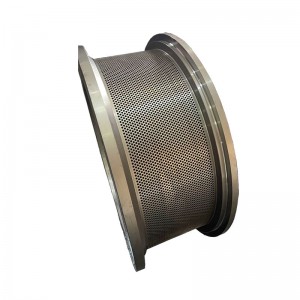

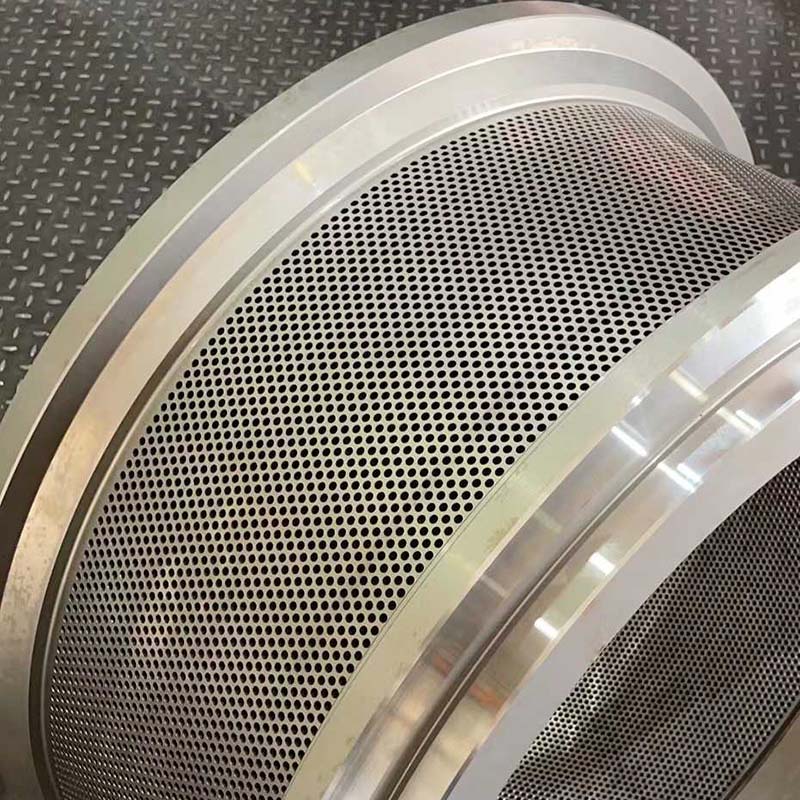

Poultry and Livestock Feed of Pellet Mill Ring Die

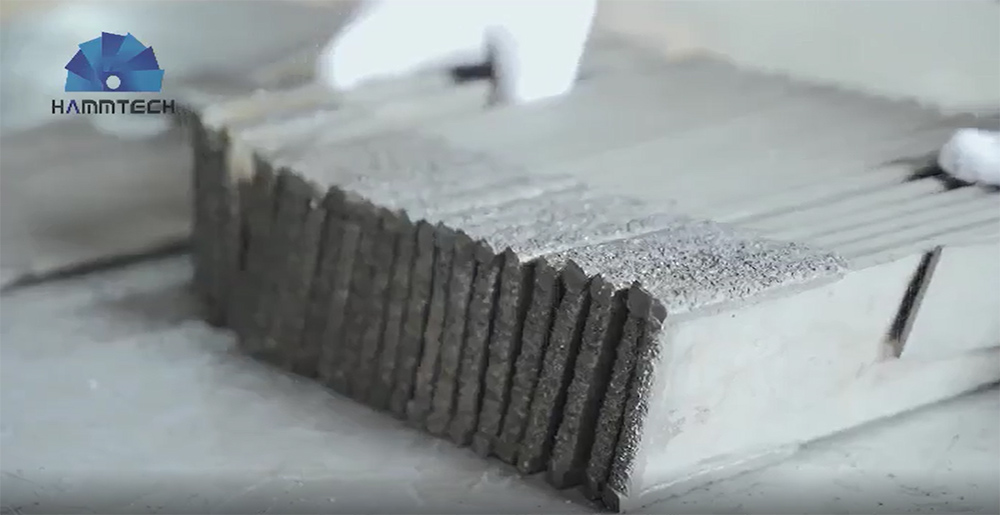

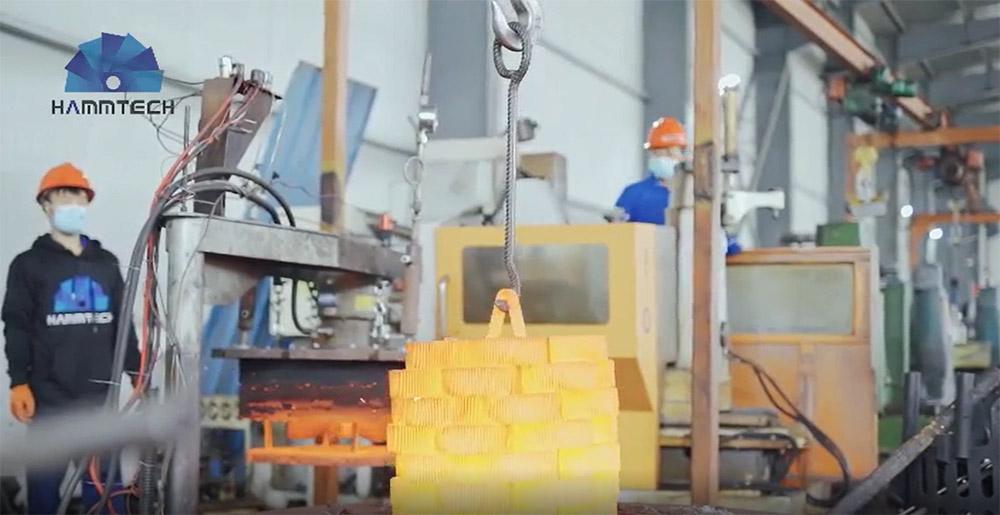

There are many factors to consider when selecting a ring die. However, in practice, some factors are usually already designed, such as the installation of the ring die, the line speed of the ring die and the working area of the ring die. These factors are decided at the time of purchase of the pellet machine. Some other factors can be ensured by choosing a professional ring die manufacturer to ensure that the ring die material, heat treatment strength and wear resistance, die hole opening rate and roughness can reach the best performance requirements.

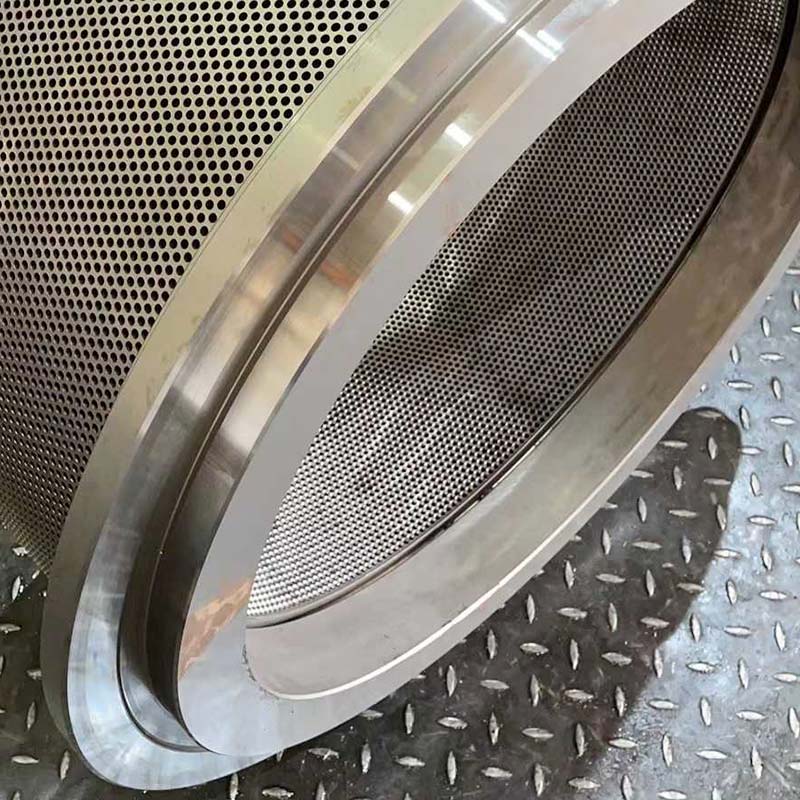

There are several ways to install a pellet mill ring die, but here are the most common ones:

Bolt joint installation: This installation method is simple, the ring die is not easy to tilt. However, if the concentricity is poor and the position degree of the ring die bolt hole does not match that of the bolt hole on the empty shaft drive wheel, the bolts may break easily when the single bolt is stressed after installation. When selecting the ring die, the supplier is required to ensure the position degree of the screw hole, and the rotary die is required to drill.

Tapered joint installation: Tapered mounting ring die has good centering performance, large torque transmission, and the ring die fixing bolt is not easy to shear off, but it requires the assembler to be careful and master certain skills, otherwise the ring die is easy to be installed inclined.

Hoop joint installation: This method is more suitable for smaller pellet mills. it is easy to install and remove. The disadvantage is that the hoop die itself is not symmetrical and cannot be used with a dropped face.