Pellet Mill Flat Die

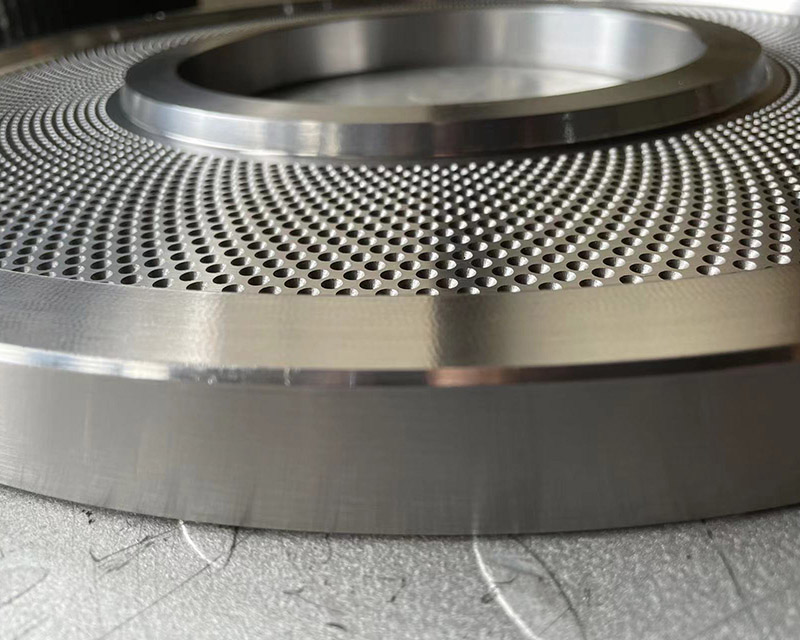

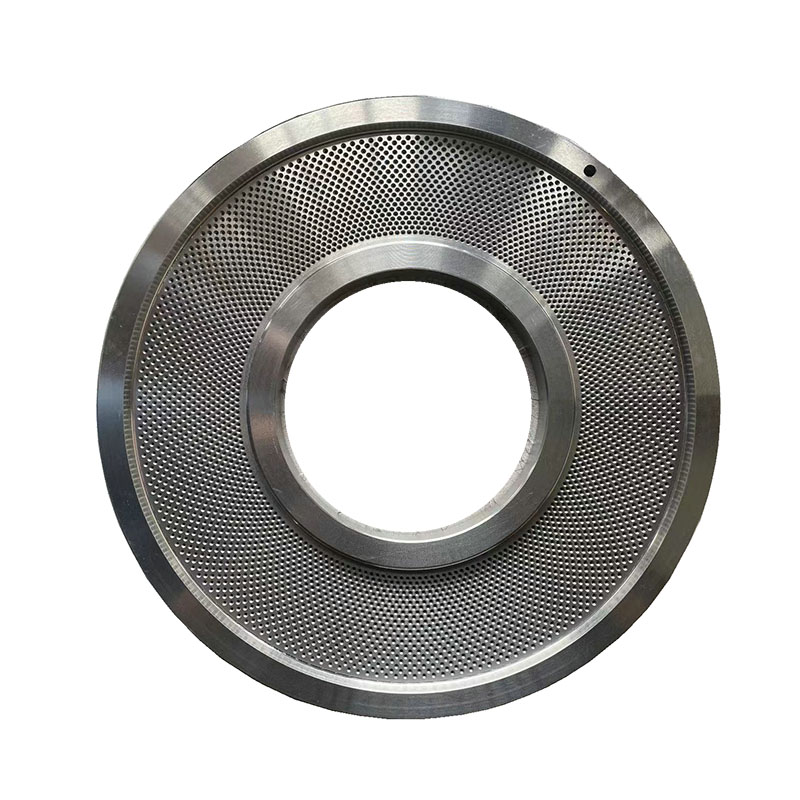

Before drilling, the round bar is cut and turned to a specific diameter and thickness, and then the dimensional tolerance and surface quality are checked. After successful measurement and testing, we receive a unique product number and have detailed technical documents to track each stage of the production process.

Before drilling, it is necessary to select the geometric shape and proper length of the hole. In order to ensure high accuracy and obtain the maximum hole flatness, high-quality drill bits are required.

The depth and angle of the counterbore will depend on the granulating material, and these parameters are key factors for the quality of the final product.

The hardness of heat treatment is HRC55-66, which has good durability, so as to improve its wear resistance and productivity. The heat treatment process shall be carried out with appropriate parameters for materials to ensure maximum hardness and appropriate resistance to eliminate the risk of cracking.

High quality products should have perfectly smooth and countersunk holes. Hammer adopts Italian imported drilling and advanced vacuum heat treatment process to avoid oxidation of horizontal holes, effectively ensure the smoothness of mold holes, and the granulated products are first-class.

In order to maintain the high quality of the granulator, the manufacturing process must be continuously supervised, and each production process must be strictly monitored to reduce the number of defective products.

Supply ODM China Pellet Machine Roller and Die and a Set of Roller and 6mm Die, We have now won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.