Mainly including material and applicability. The following is an analysis of several common hammer blade materials and their applicable materials:

Low carbon steel: Low carbon steel hammer blades are suitable for general material crushing, such as grains, straw, etc. Its advantage is lower cost, but lower wear resistance and hardness, making it suitable for handling softer materials.

Medium carbon steel: Medium carbon steel hammer blades have good hardness and wear resistance, suitable for materials with moderate hardness, such as tree branches, small tree branches, etc. It has good durability, but the cost is relatively high.

Special cast iron: Special cast iron hammers are suitable for processing harder materials such as bones, ores, etc. This type of hammer has good wear resistance, but it is difficult to process.

Quenching treatment: Hammer pieces that have undergone quenching treatment have higher hardness and are suitable for processing high hardness materials such as nuts, bones, etc. Its wear resistance and service life are relatively long.

Carburizing and quenching: The hammer pieces treated with carburizing and quenching have higher hardness and wear resistance, and are suitable for processing extremely hard materials such as stones, ores, etc. This processing method can significantly improve the service life of the hammer blade.

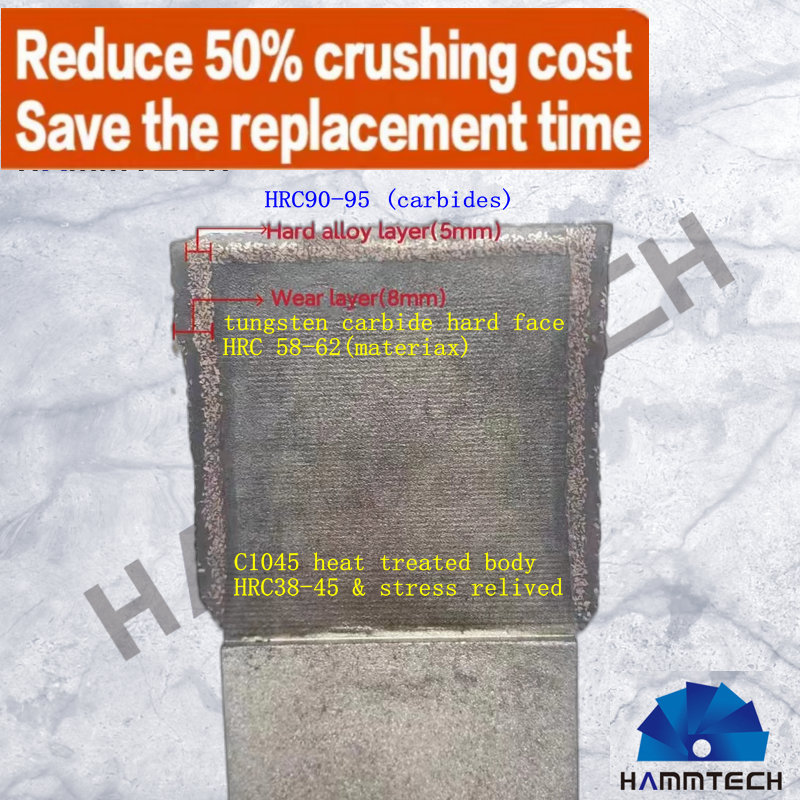

Tungsten carbide: Tungsten carbide hammer is currently one of the hardest materials on the market, suitable for processing extremely hard materials such as stones, ores, etc. Its wear resistance and service life are very long, but the cost is relatively high.

The advantages and disadvantages of hammer blades made of different materials are as follows:

Low carbon steel: Low cost, but low wear resistance and hardness.

Medium carbon steel: high hardness and durability, but high cost.

Special cast iron: good wear resistance, but difficult to process.

Quenching treatment: high hardness and long service life.

Carburizing and quenching: extremely high hardness, long service life, but high cost.

Tungsten carbide: has the highest hardness and extremely long service life, but the highest cost.

Choosing the appropriate hammer material requires consideration of factors such as material hardness, processing requirements, and cost.

Post time: Feb-28-2025