Compared with traditional manganese steel or tool steel, tungsten carbide hammers have significant advantages in wear resistance and service life. Although manganese steel or tool steel also has certain wear resistance, tungsten carbide hammer mill blade has higher hardness and stronger wear resistance, especially when dealing with hard materials.

Tungsten carbide hammer knife crusher is widely used for coarse and medium crushing of various materials with compressive strength below 320 megapascals. It has a large crushing ratio, easy operation, adaptability to various types of materials, and strong crushing power, and occupies a large proportion in the field of crushing equipment. Hammer knife crusher is suitable for crushing various brittle materials and minerals, and has been widely used in various industries such as electronics, medicine, ceramics, polycrystalline silicon, aerospace, optical glass, batteries, three base fluorescent powder batteries, new energy, metallurgy, coal, ore, chemical industry, building materials, geology, etc. In addition, the crusher can change the gap between user needs and adjust the discharge particle size to meet the different needs of different crusher users. Hammer knife crushers mainly rely on impact to crush materials. The crushing process is roughly as follows: the material enters the crusher and is crushed by the impact of the high-speed rotating hammer head. The crushed material obtains kinetic energy from the hammer head and rushes towards the baffle and sieve bar inside the frame at high speed. At the same time, the materials collide with each other and are crushed multiple times. Materials smaller than the gap between the sieve bars are discharged from the gap, and some larger materials are crushed again by the impact, grinding, and squeezing of the hammer head on the sieve bar. The material is extruded from the gap by the hammer head, thereby obtaining the desired particle size product.

Product features:

1. Extremely low wear (PPM) can prevent material contamination.

2. Long service life and low overall operating costs.

3. The hammer head is made of tungsten carbide material, which is wear-resistant, corrosion-resistant, impact resistant, and high-temperature resistant.

4. When working, the dust is small, the noise is low, and the operation is smooth.

Tungsten carbide hammers is suitable for crushing various materials, including hard materials such as corn, soybean meal, sorghum, etc. Tungsten carbide hammer pieces have high hardness and wear resistance, which can effectively reduce wear and prolong service life during the crushing process. In addition, tungsten carbide hammer pieces also have acid resistance, alkali resistance, low temperature resistance, fire resistance and other properties, suitable for various harsh working environments.

Characteristics and Application Scenarios of Tungsten Carbide Hammer beater

High hardness: Tungsten carbide hammer beater have extremely high hardness and can cut and crush almost any other material.

Wear resistance: Due to its high hardness, tungsten carbide hammer mill beater wear very little during the crushing process and are suitable for long-term use.

High temperature resistance: Tungsten carbide hammer beater has excellent high temperature resistance and can maintain its performance during high-speed operation.

Wide applicability: Suitable for various harsh working environments, such as acid resistance, alkali resistance, low temperature resistance, fire resistance, etc.

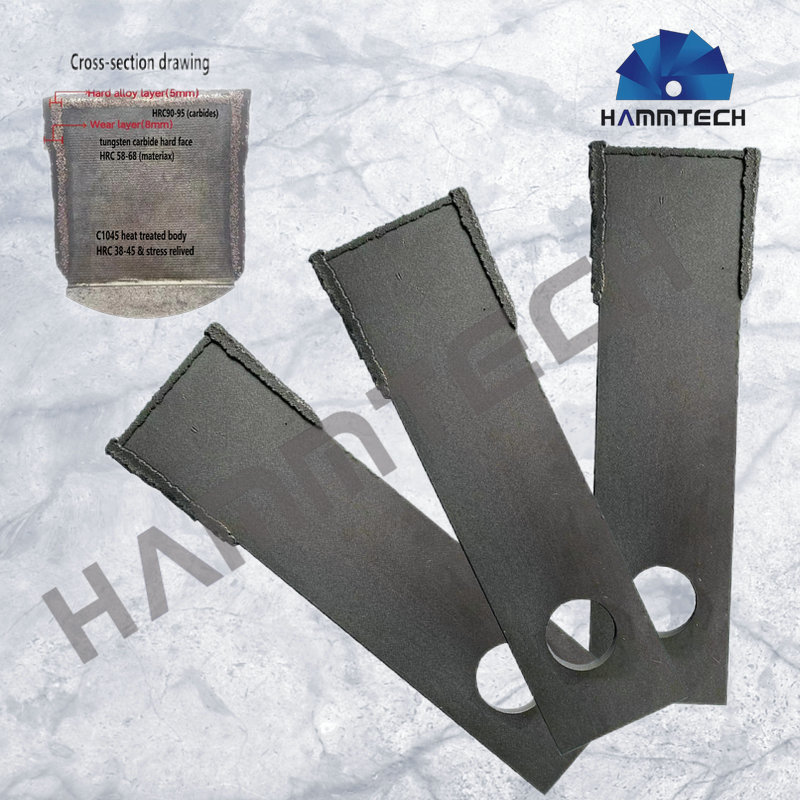

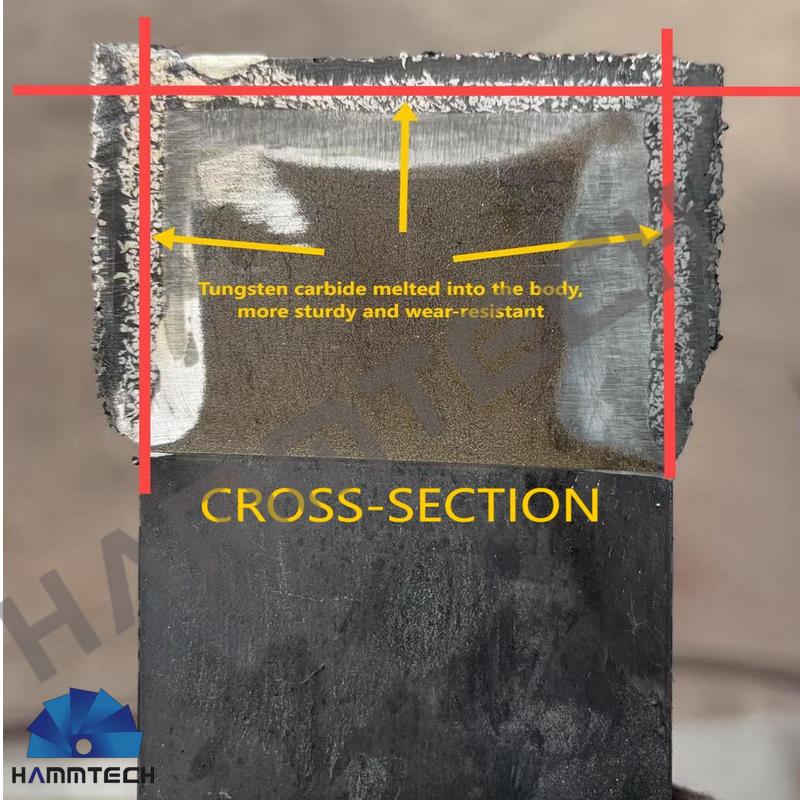

The uniqueness of our tungsten carbide hammer blades;

We adopt the hard alloy particle welding technology, which forms a high-temperature metal melt pool on the surface of the workpiece, and uniformly sends the hard alloy particles into the melt pool. After cooling, the hard alloy particles form a hard alloy layer. Due to the melting and solidification of the metal body, a wear-resistant layer is formed, and there are no issues such as dissimilar welding cracks or peeling.

Post time: Dec-20-2024