1. The crusher experiences strong and abnormal vibrations

Reason: The most common cause of vibration is due to the imbalance of the turntable, which can be caused by incorrect installation and arrangement of the hammer blades; The hammer blades are severely worn and have not been replaced in a timely manner; Some hammer pieces are stuck and not released; Damage to other parts of the rotor leads to weight imbalance. Other issues causing vibration include: deformation of the spindle due to play; Severe bearing wear can cause damage; Loose foundation bolts; The hammer speed is too high.

Solution: Reinstall the hammer blades in the correct order; Replace the hammer blade to ensure that the weight deviation of the hammer blade does not exceed 5g; Power off inspection, manipulate the hammer to make the stuck piece rotate normally; Replace damaged parts of the turntable and balance it; Straighten or replace the spindle; Replace bearings; Lock the foundation bolts tightly; Reduce the rotational speed.

2. The crusher makes abnormal noise during operation

Reason: Hard objects such as metals and stones enter the crushing chamber; Loose or detached parts inside the machine; The hammer broke and fell off; The gap between the hammer and sieve is too small.

Solution: Stop the machine for inspection. Tighten or replace parts; Remove hard objects from the crushing chamber; Replace the broken hammer piece; Adjust the clearance between the hammer and sieve. The optimal clearance for general grains is 4-8mm, and for straw, it is 10-14mm.

3. The bearing is overheated, and the temperature of the crushing machine casing is very high

Reason: Bearing damage or insufficient lubricating oil; The belt is too tight; Excessive feeding and long-term overload work.

Solution: Replace the bearing; Add lubricating oil; Adjust the tightness of the belt (press the middle of the transmission belt with your hand to create an arc height of 18-25mm); Reduce the feeding amount.

4. Inverted air at the feed inlet

Reason: Blockage of fan and conveying pipeline; Blockage of sieve holes; The powder bag is too full or too small.

Solution: Check if the fan is excessively worn; Clear the sieve holes; Timely discharge or replace the powder collection bag.

5. The discharge speed has significantly decreased

Reason: The hammer blade is severely worn; Overloading of the crusher causes the belt to slip and results in low rotor speed; Blockage of sieve holes; The gap between the hammer and sieve is too large; Uneven feeding; Insufficient supporting power.

Solution: Replace the hammer blade or switch to another corner; Reduce load and adjust belt tension; Clear the sieve holes; Reduce the gap between the hammer and sieve appropriately; Uniform feeding; Replace the high-power motor.

6. The finished product is too coarse

Reason: The sieve holes are severely worn or damaged; The mesh holes are not tightly attached to the sieve holder.

Solution: Replace the screen mesh; Adjust the gap between the sieve holes and the sieve holder to ensure a tight fit.

7. Belt overheating

Reason: Improper tightness of the belt.

Solution: Adjust the tightness of the belt.

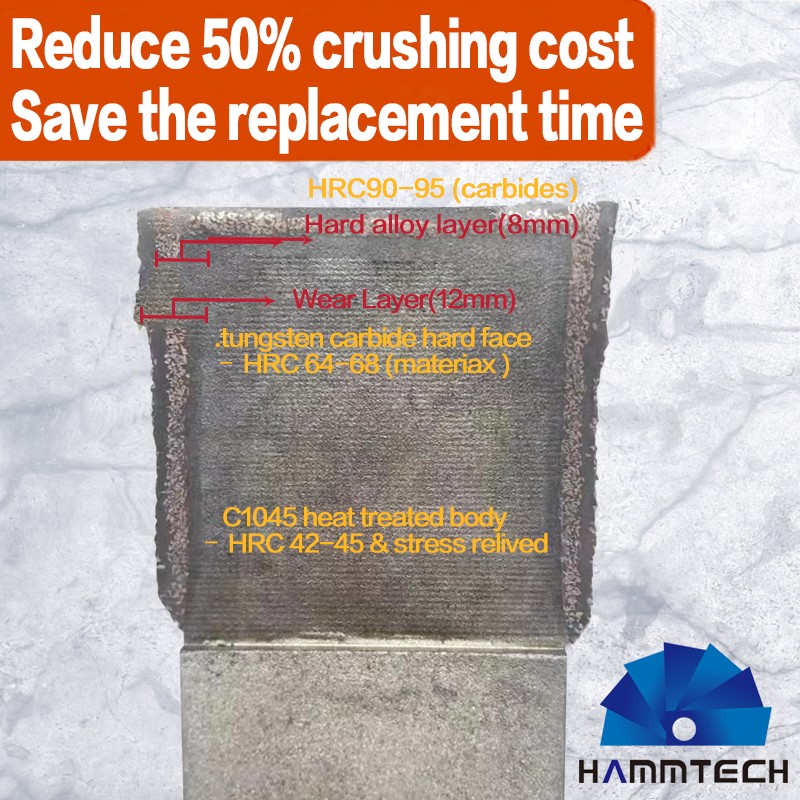

8. The service life of the hammer blade becomes shorter

Reason: Excessive moisture content in the material increases its strength and toughness, making it more difficult to crush; The materials are not clean and mixed with hard objects; The gap between the hammer and sieve is too small; The quality of the hammer blade is too poor.

Solution: Control the moisture content of the material to no more than 5%; Minimize the content of impurities in materials as much as possible; Adjust the clearance between the hammer and sieve appropriately; Use high-quality wear-resistant hammer pieces, such as Nai's three high alloy hammer pieces.

Post time: Feb-28-2025