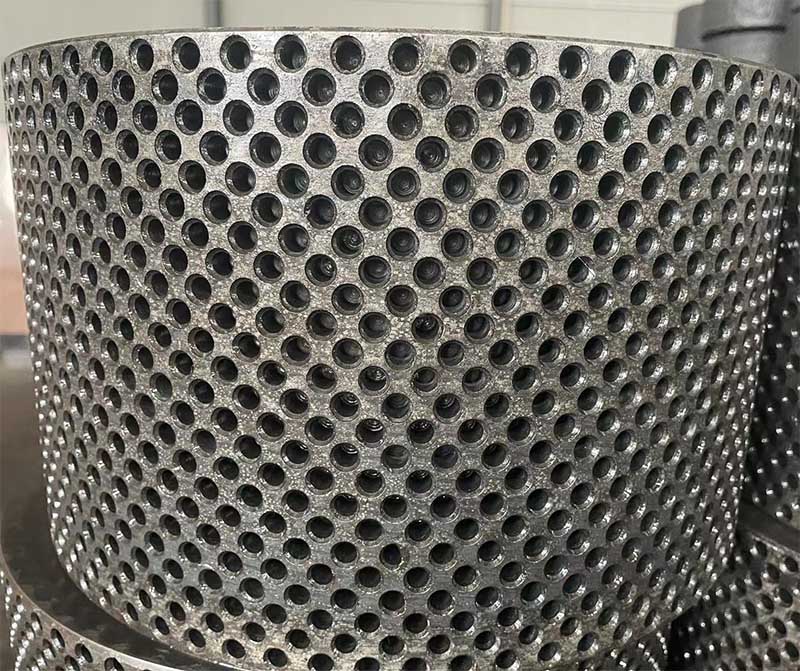

Hole Teeth Roller Shell

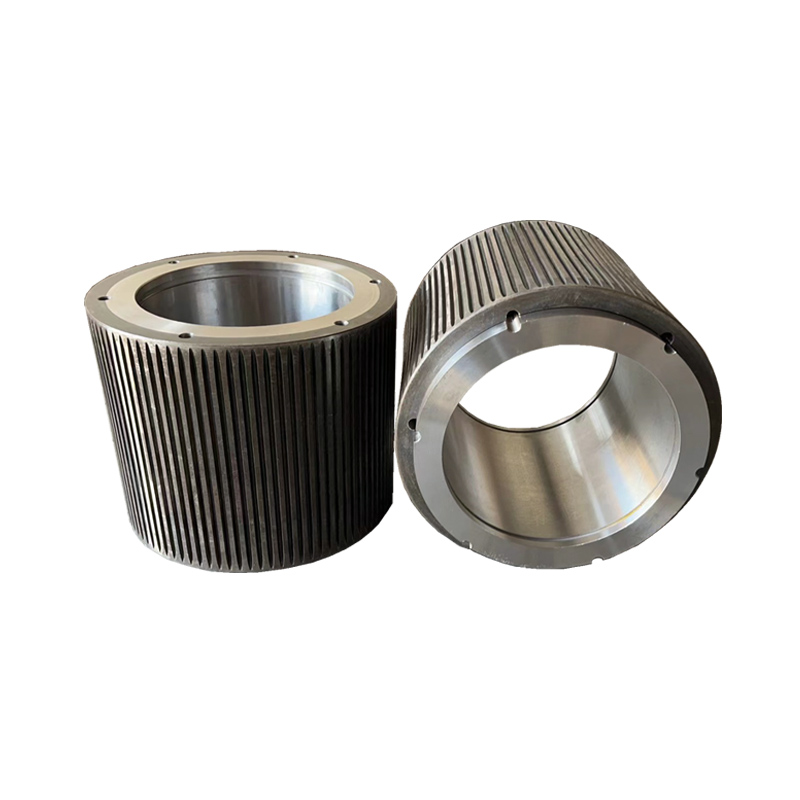

A dimpled roller shell is a component used in the manufacturing of pellet mills, which are machines that are used to produce animal feed pellets, biomass pellets, and other types of compressed pellets.

The special feature of this roller shell is the presence of small dimples on its surface. The dimples serve to increase the surface area of the roller, which helps to improve the quality of the pellets being produced. By increasing the surface area, the dimples allow for better heat transfer during the pelletizing process, which can result in more consistent and higher quality pellets.

The use of dimpled roller shells in pellet mills can help to improve the efficiency and effectiveness of the pelletizing process, resulting in high-quality pellets and increased productivity.

Regular maintenance and inspection of the roller shell should be conducted to ensure that it is in good working condition. Here are some steps to follow for maintaining a pellet mill roller shell:

1. Inspect the roller shell for signs of wear and tear, cracks, or other damage. If any damage is detected, replace the roller shell immediately to prevent further damage to the pellet mill.

2. Clean the roller shell regularly to prevent the buildup of dust and debris. Use a brush or air blower to remove any residue or foreign objects from the surface of the roller shell.

3. The gap between the roller shell and the die should be adjusted regularly to ensure optimal pellet quality and production efficiency. Follow the manufacturer's instructions for adjusting the gap.

4. Lubricate the roller shell regularly with a high-quality lubricant. Make sure to follow the manufacturer's instructions for lubrication.

5. Avoid overloading the pellet mill or operating it at a high speed, as this can cause excessive wear on the roller shell.

6. Avoid using abrasive materials in the pellet mill as this can cause damage to the roller shell.

7. Always follow the manufacturer's recommendations for maintenance and operation.