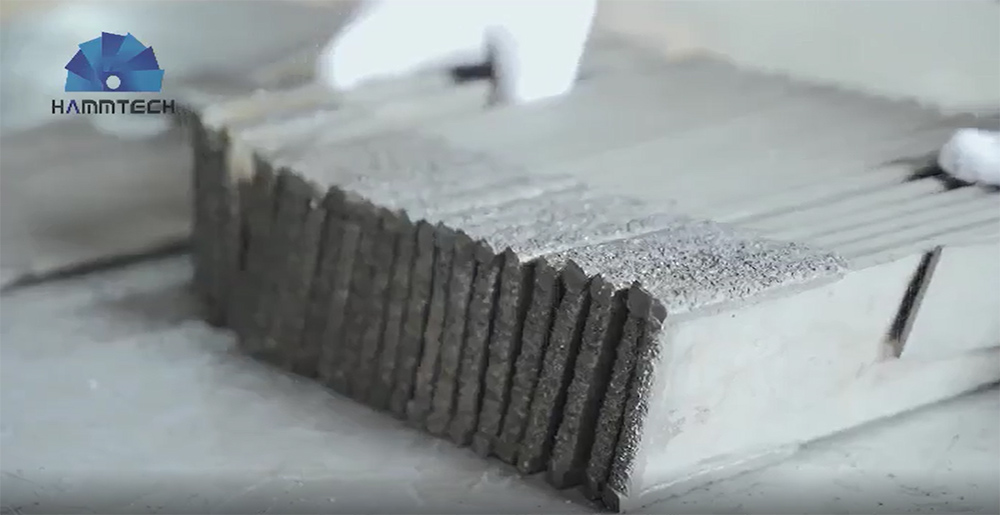

Helical Teeth Roller Shell

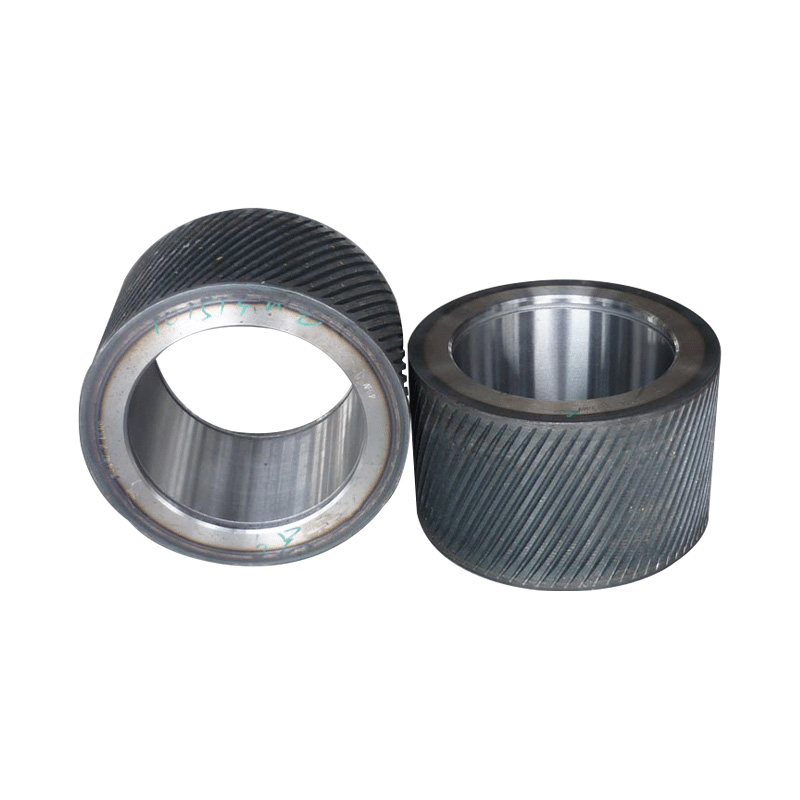

Why it is important to adjust the gap between the pellet mill ring die and roller?

The correct adjustment of the die roller gap is an important condition to achieve maximum capacity and extend the life of the pressure roller and ring die. The most suitable gap for the ring die and roller is 0.1-0.3 mm. When the gap is greater than 0.3mm, the material layer is too thick and unevenly distributed, reducing the granulation output. When the gap is less than 0.1mm, the machine wears seriously. Generally, it is good to turn on the machine and adjust the pressure roller when it is not turning or to grab the material by hand and throw it into the granulator to hear a banging sound.

What are the implications when the gap is too small or too large?

Too small: 1. The ring die is delayed; 2. The pressure roller is excessively worn; 3. In severe cases, this can lead to the breakage of the ring die; 4. The vibration of the granulator increases.

Too large: 1. The pressure roller slipping system does not produce the material; 2. The eating material layer is too thick, blocking the machine frequently; 3. The granulator efficiency is reduced (the granulation host can easily reach full load, but the feed can not be elevated).