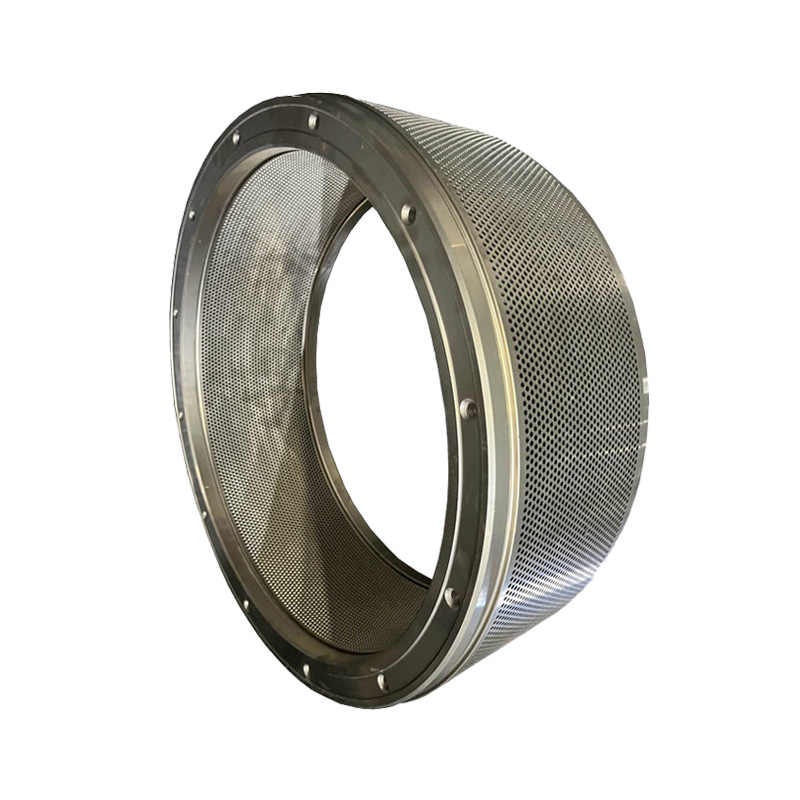

Fish Feed Pellet Mill Ring Die

In order to control the uniformity of the hardness of the ring die after heat treatment, after heat treatment of each ring die, in each part of the circumferential direction of three equal parts, take no less than 3 points to measure the average value of hardness. The difference between the hardness of each part should not be greater than HRC4.

In addition, the hardness of the blank of the ring die should be controlled, and the hardness should be between HB170 and 220. If the hardness is too high, the drill bit is easy to break and cause dead holes. If the hardness is too low, the finish of the die holes will be affected. In order to control the uniformity of the material inside the blank, if possible, each blank should be carried out internal inspection, to prevent the blank internal cracks, pores, sand, and other defects.

Roughness is also an important index to measure the quality of ring die. At the same compression ratio, the greater the roughness value, the greater the resistance to extrusion and the more difficult it is to discharge the feed. A suitable roughness value should be between 0.8 and 1.6.

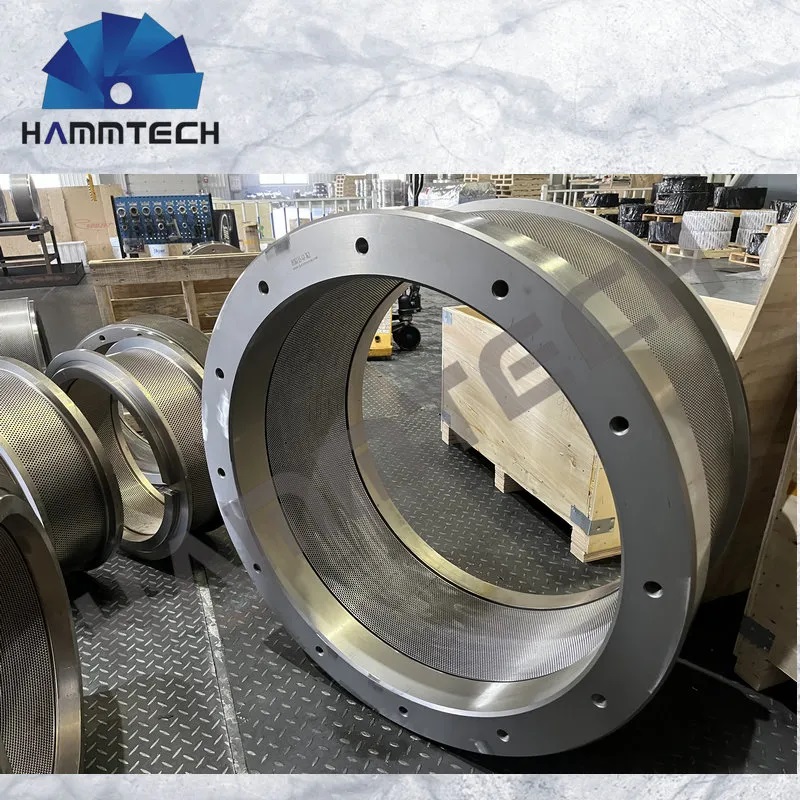

1. The ring die is wrapped in a waterproof plastic film.

2. Wooden package or customized as per customers' request.

3. Standard exporting package which is suitable for long-distance transportation.

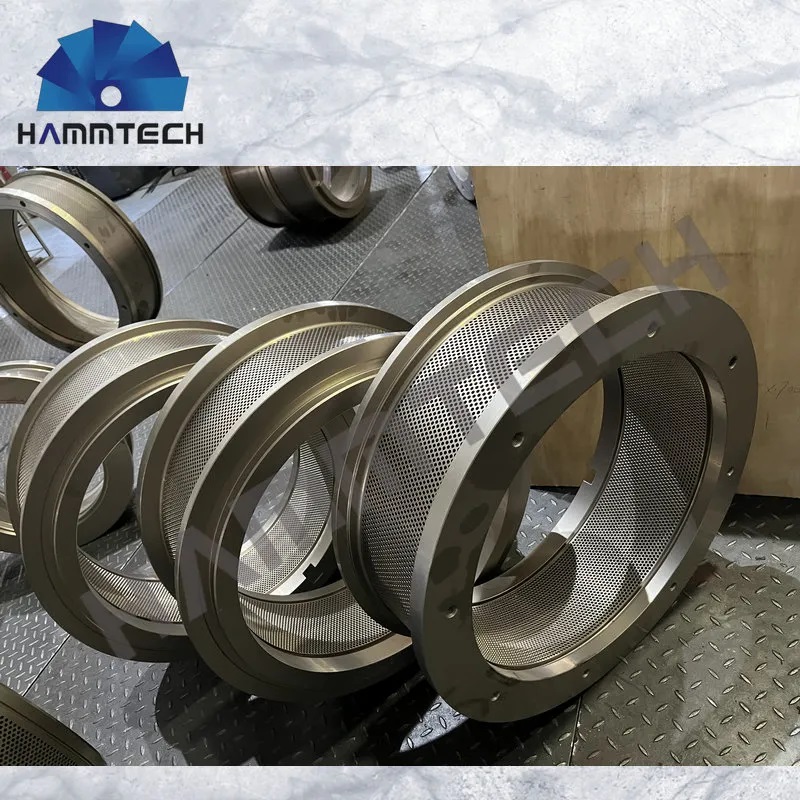

Since 2006, HAMMTECH has been providing professional feed machinery accessory solutions to customers worldwide.

HAMMTECH is a one-stop accessories supplier.

HAMMTECH serves customers in more than 30 countries.

We produce different types of products for a wide range of industries such as feed pellet mills, biomass pellet mills, and biomedicals.