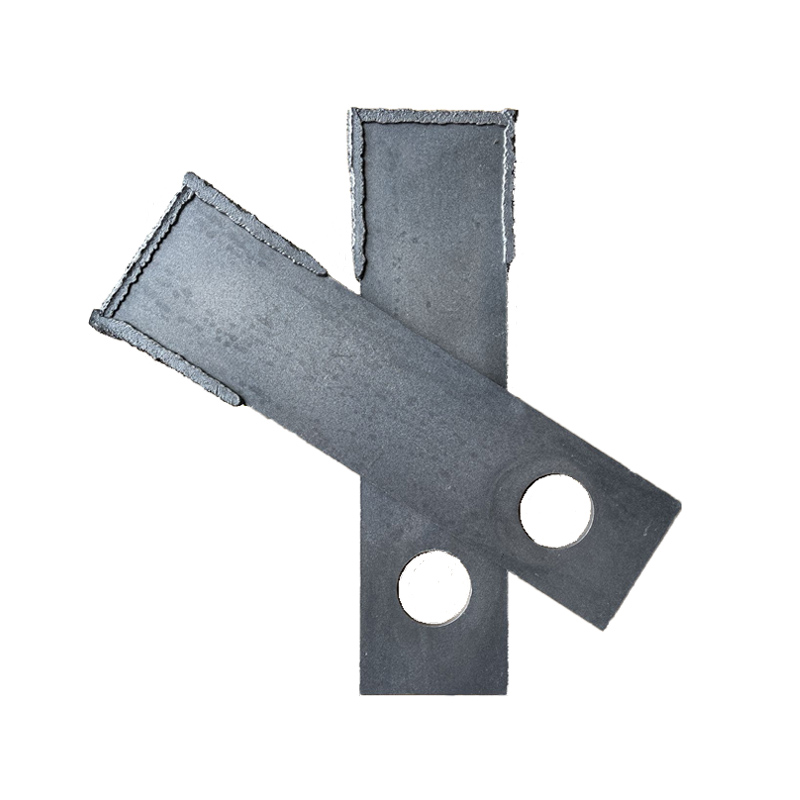

Double Hole Smooth Plate Hammer Blade

Hammer blade materials include: low carbon steel, medium carbon steel, special cast iron, etc.

Heat treatment and surface hardening can improve the wear resistance of the hammer blade head, thus extending its service life of the hammer blade head.

The shape, size, arrangement and production quality of hammer blade pieces have a great influence on grinding efficiency and finished product quality.

1. Shape: double head double hole

2. Size: various sizes, customized.

3. Material: high quality alloy steel, wear-resistant steel

4. Hardness: around the hole: hrc30-40, the head of hammer blade hrc55-60. The wear angle is increased and thickened; The wear-resistant layer reaches 6mm, which is a product with super cost performance

5. The proper length is conducive to improving the electric energy output. If the length is too long, the electric energy output will be reduced.

6. High dimensional accuracy, good finish, high performance and long-last lifespan.

7. It is always pre-assembled for easy installation.

We can check your current hammer blade piece and evaluate which type of surfacing pattern is more beneficial to your production process. We can design and manufacture hammer blade sets to reduce downtime and improve efficiency when replacing hammer blade sets. We can manufacture various hammer blade pieces for different types of hammer mills.

We also accept customized products according to customer’s needs, with high precision, high efficiency and high quality.

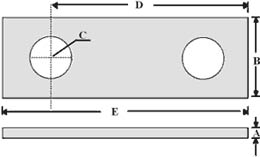

Please provide the size of hammer blades according to the following diagram.

Dimensions of hammer blades

A: Thickness

B: Width

C: Diameter to fit rod size

D: Swing Length

E: Total Length