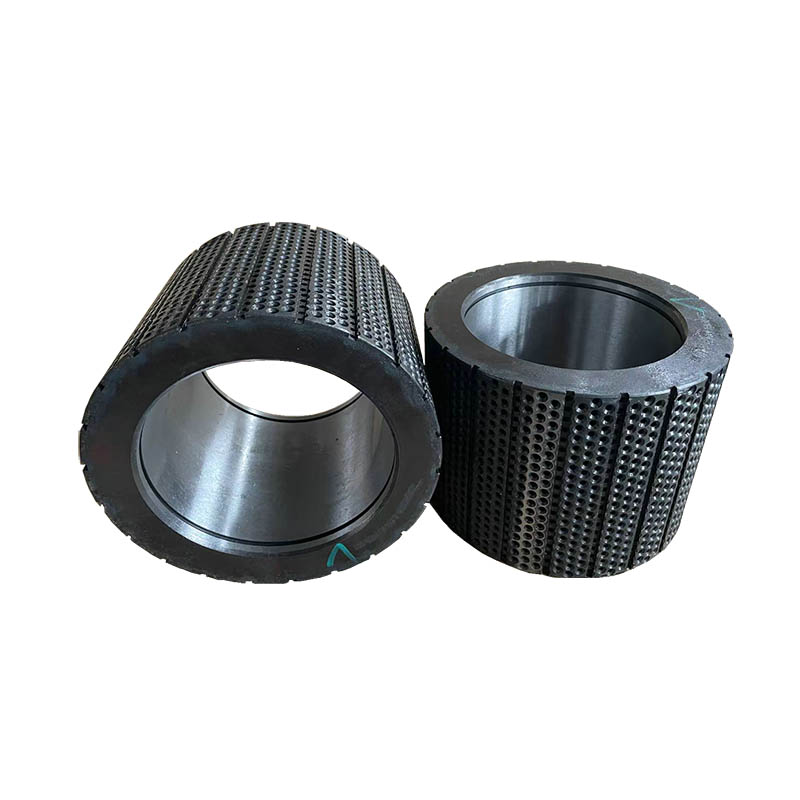

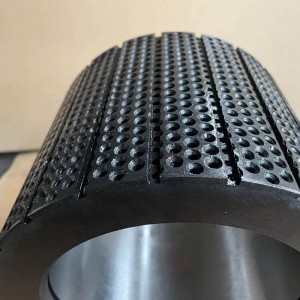

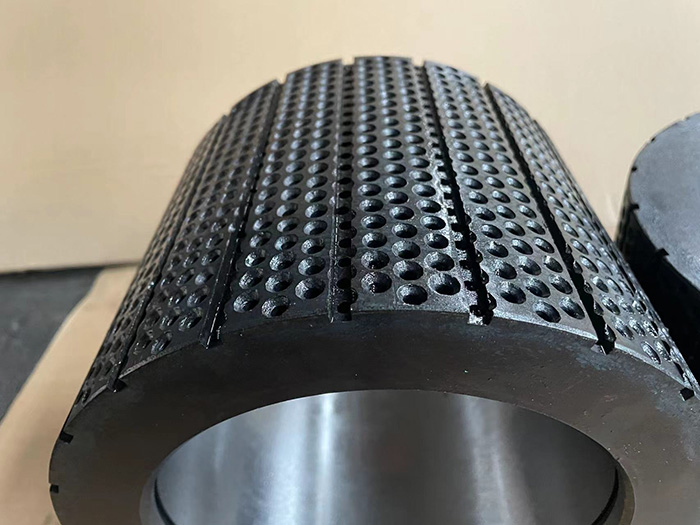

Dimpled Roller Shell for Pellet Machine

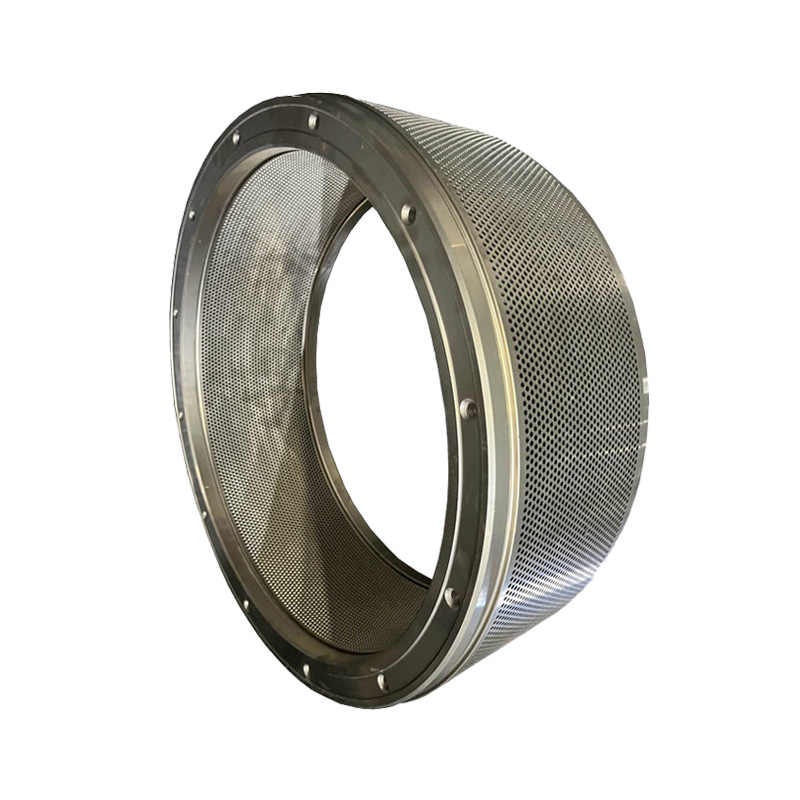

What is a pellet mill roller shell?

Roller shells are used in a variety of industrial equipment and machinery. The pellet mill roller shell is a crucial component of a pellet mill, which is used to produce pellets from biomass and other materials. The roller shell is responsible for shaping the raw material into uniform pellets. The raw material is fed into the pellet mill, where it is compressed and formed into a pellet by the roller shell and a die.

What's the materials of roller shells?

The materials used for making roller shells vary depending on the type of pellet mill and the type of material being processed. Commonly used materials include high-quality steel, cast iron, stainless steel, and alloy steel. Each material offers different levels of heat resistance and durability that can withstand the high pressures and wear associated with pellet production.

What's the function of pellet mill roller shell?

The roller shells are grooved in order to press raw materials into pellets. In addition to shaping the raw material, the roller shell also helps to maintain the temperature of the pellet mill, as the heat generated during the pelletization process is absorbed by the roller shell and dissipated through its surface. This helps to ensure consistent pellet quality and production efficiency.

We offer a full range of roller shells of any dimension and type for all pellet mills including corrugated, dimpled, helical, closed-end, open-end, fishbone cutting, etc. The type of roller shell you choose will depend on your desired pellet size, production rate, and cost. Please feel free to contact us and we are sure you will get exactly the one you need.