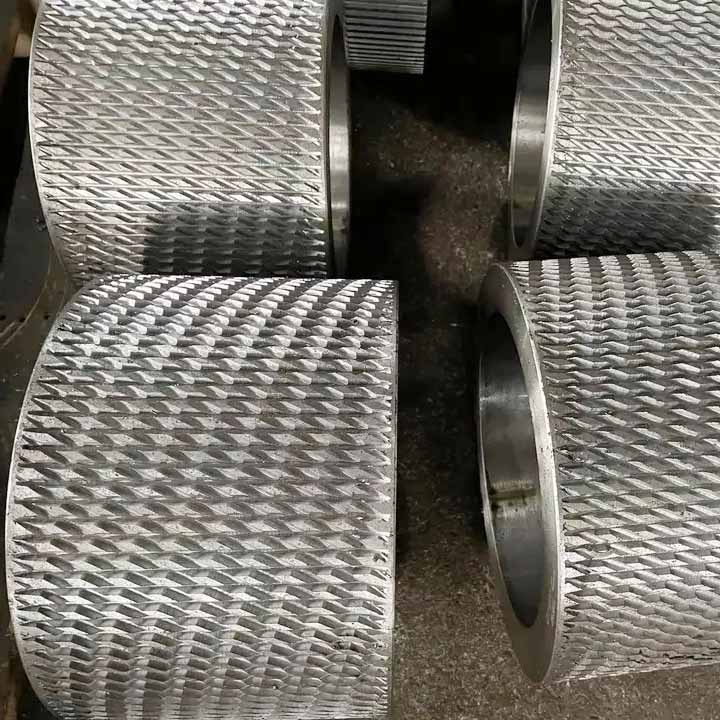

Cross Teeth Roller Shell

● Material: 100Cr6, 16MnCr5, 48Mn, 40Cr, C50, 20CrMnTi, 20CrMn5.

● Heat treatment: the carburized surface hardness reaches 58-60HRC, the carburized layer depth is 1.6mm, the medium frequency surface hardness reaches 52-58HRC, and the hard layer depth of 50HRC is 5mm. Ensuring better wear resistance, and granulation performance.

● Surface: cross-type teeth on the surface

● The precision turning process is all CNC controlled to ensure that all parts are dimensionally accurate.

● Long working life

Changzhou Hammermill Machinery Technology Co., Ltd(HAMMTECH) is a factory specializing in producing accessories for hammer mills and pellet mills, such as hammer blades, hammer beaters, roller shells, flat dies, ring dies, sugar cane chopping carbide blades and other feed machinery accessories.

Raw Materials Storage Area

Carburizing and Quenching

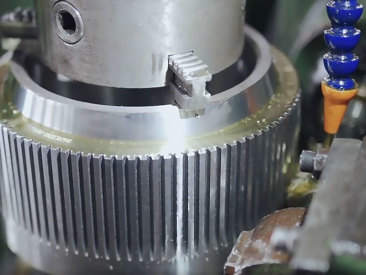

Roller Hobbing

Screen Hole Drilling

Quality Inspection

Finished Products Area