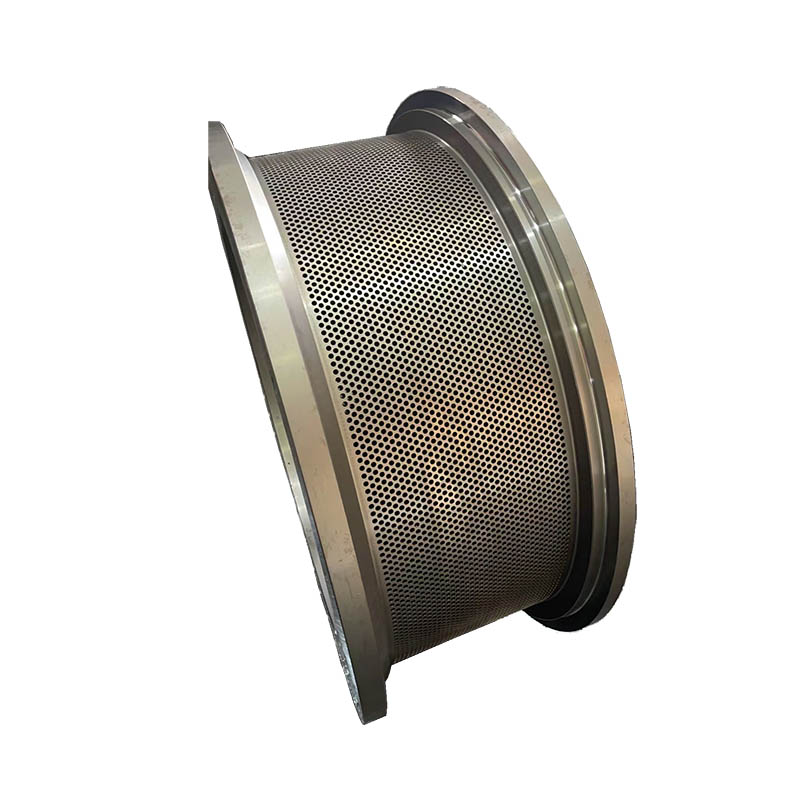

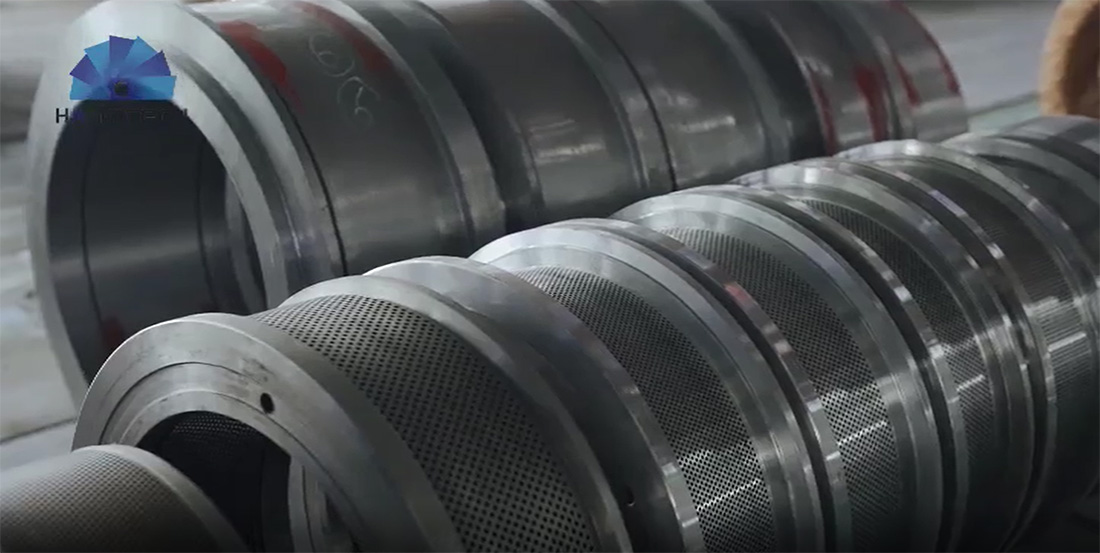

Crab Feed Pellet Mill Ring Die

New ring die polishing

Due to the attachment of some iron chips and oxides on the inner wall of the die hole, the new ring die should be polished before use to make the inner wall of the die hole smooth, reduce friction resistance, and improve the granulation yield.

Polishing methods:

(1) Use a drill with a diameter smaller than the aperture of the die to clean up the debris blocking the die hole.

(2) Install the ring die, wipe a layer of grease on the feed surface, and adjust the spacing between the roller and die.

(3) With 10% fine sand, 10% soybean meal powder, 70% rice bran mixed, and then mixed with 10 % grease with abrasive, start the machine into the abrasive, processing 20 ~ 40min, with the increase of die hole finish, the particles gradually loose.

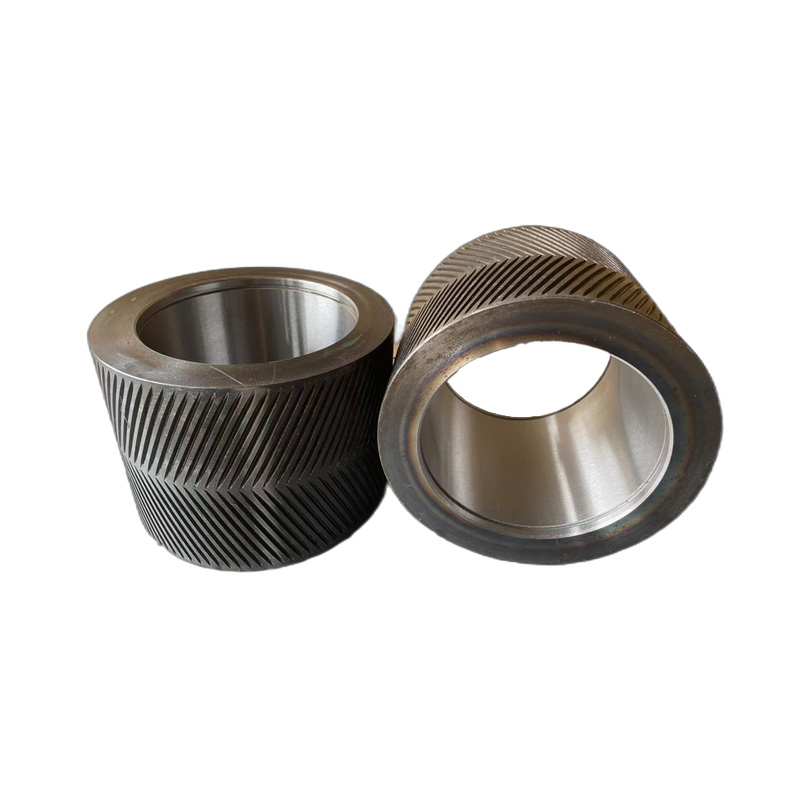

Adjust the working gap between the ring die and the press roller

Correct adjustment of the working gap between the ring die and the pressure roller is the key to the use of the ring die. Generally speaking, the gap between the ring die and the press roller should be between 0.1 and 0.3 mm. Normally, the new press roller and the new ring die should be matched with a slightly larger gap, and the old roller and the old ring die should be matched with a smaller gap. The large aperture ring die should be used with a slightly larger gap, the small aperture ring die should be used with a slightly smaller gap. The material that is easy to granulate is suitable for the large gap, the material that is difficult to granulate should be used with a small gap.

Other cautions

* During the use of the ring die, it is necessary to avoid mixing sand, iron, bolts, iron filings, and other hard particles in the material, so as not to speed up the wear of the ring die or cause too much impact on the ring die. If any iron enters the die hole, it must be flushed out or drilled out in time.

* The ring die must not be tilted after installation, otherwise, it will produce uneven wear; the bolts tightening the ring die must reach the required locking torque to avoid bolt shearing and ring die damage.

* After using the ring die for a certain period of time, it should be checked regularly whether the die hole is blocked by materials and cleaned in time.