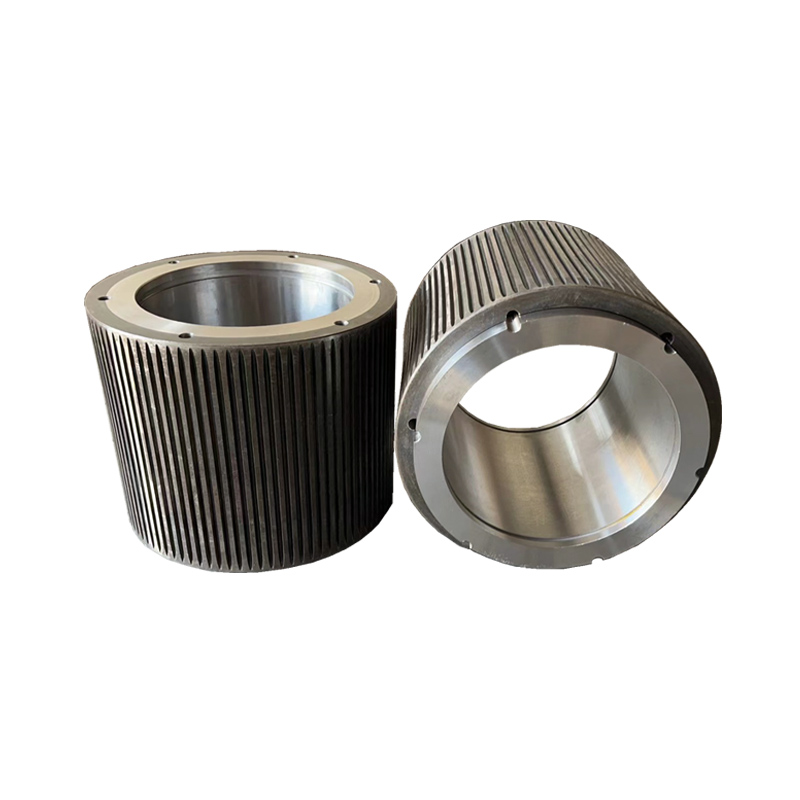

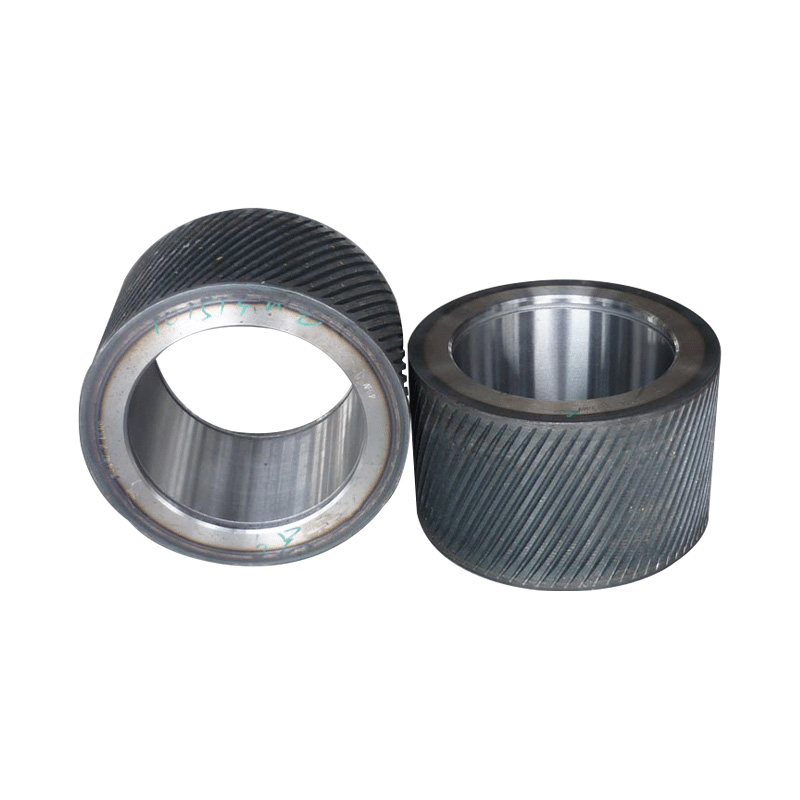

Closed-End Roller Shell for Pellet Mill

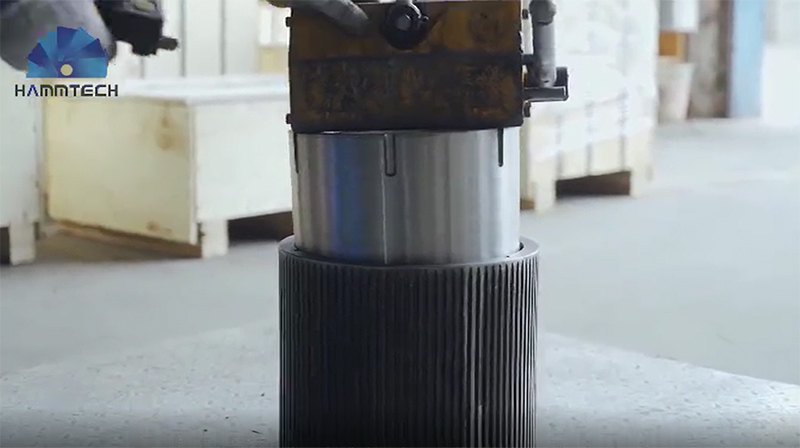

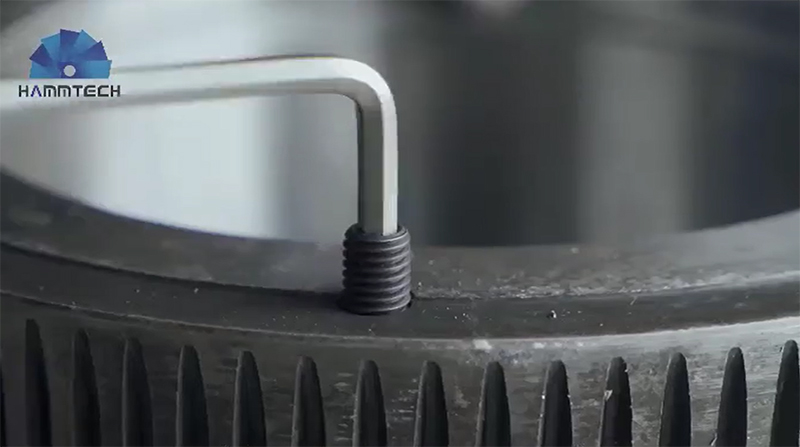

The roller shell is one of the main working parts of the feed pellet mill, which is used to process various biofuel particles, animal feed and other particles. It adopts a high wear-resistant diamond, carburizing heat treatment and uniform hardness. It has a long service life. There are different types of structures, such as through type, through type and pass type. The pressure bar part is composed of internal eccentric shaft and other components, which are accurate in size, convenient for adjusting the distance between the pressure roller and the ring mold according to the user's production requirements, and easy to fold and install, and easy to replace the pressure roller shell.

● Material: 100Cr6, 16MnCr5, 48Mn, 40Cr, C50, 20CrMnTi, 20CrMn5.

● Heat treatment: the carburized surface hardness reaches 58-60HRC, the carburized layer depth is 1.6mm, the medium frequency surface hardness reaches 52-58HRC, and the hard layer depth of 50HRC is 5mm.

● Pellet mill roller shell type: feed roller shell, delicate chemical roller shell, sawdust roller shell, biomedical roller shell, etc.

● Tooth of roller shell: straight tooth, helical tooth, circular arc tooth, hole type tooth, cross-type tooth, Tungsten Carbide roller shell, etc.

We can provide 90% roller shell of the pellet mill. Roller shells can be customized.

Awila420, Bilco360, Buhler350, Buhler400, Buhler420, Buhler520, Buhler660, CPM2016, CPM3016, CPM3020, CPM3022, CPM7726, CPM7932,CPP150, CPP200, CPP360, CPP300, CSP020, IDAH530, IDAH530F, IDAH635D, MUZL350, MUZL420, MUZL420T, MUZL420TW, MUZL550, MUZL600, MUZL600T, MUZL610TW, MUZL1200, MUZL1210C, MUZL1610C, MZLH250, MZLH320, MZLH350, MZLH400, MZLH420, MZLH508, MZLH678, MZLH768, SZLH250, SZLH320, SZLH350, SZLH400, SZLH420, SZLH508, SZLH678, SZLH768/SZLJ20, SZLJ320, SZLJ350, SZLJ400, SZLJ420, SZLJ508, OGM-0.8, OGM-1.5, OGM-6,Van Arson C600, Van Arsen750, Van ArsenC900, XGJ560, XGJ850, PTN580, PTN580-C,YEMMAK520, KAHL37-850.