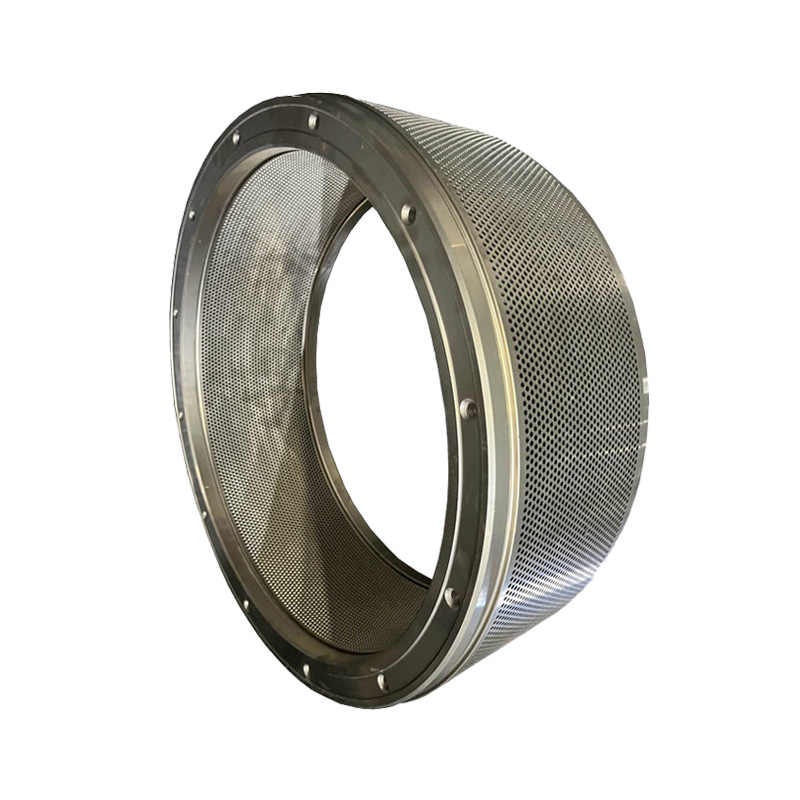

Cattle and Sheep Feed Pellet Mill Ring Die

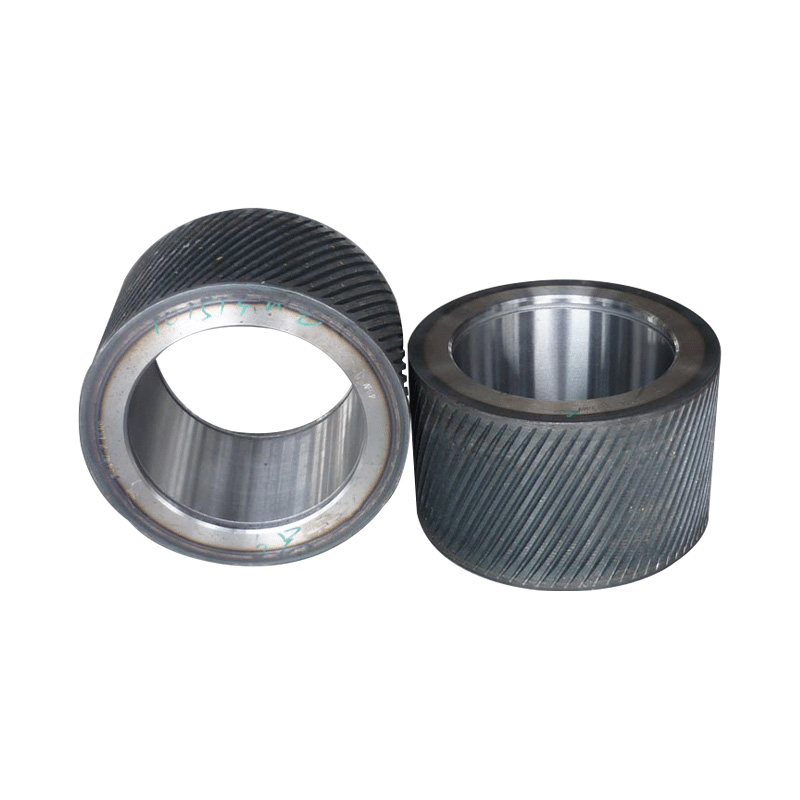

A pellet mill ring die is a cylindrical component that is used in pellet mills to shape pellets. The die is made up of several components, including the die body, die cover, die holes, and die groove. Among these, the die holes are the most critical part of the ring die since they are responsible for shaping the pellets. They are evenly spaced around the circumference of the die and are typically between 1-12mm in diameter, depending on the type of pellet being produced. The die holes are created by drilling or machining the die body, and they must be precisely aligned to ensure the correct size and shape of the pellets.

Outside Holes

Inside Holes

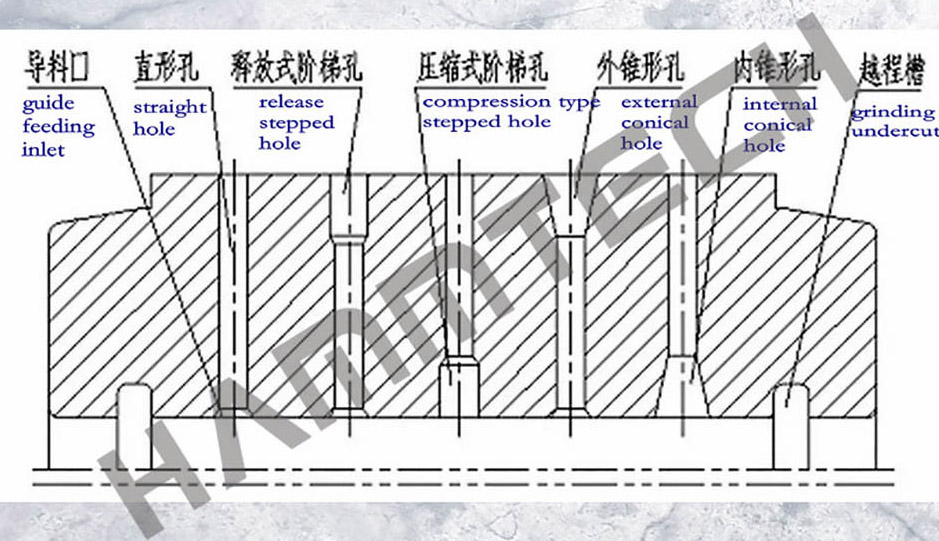

The common ring die holes are mainly straight holes, stepped holes, external conical holes, and internal conical holes. The stepped holes are also divided into release-type stepped holes (commonly known as decompression holes or release holesdie) and compression-type stepped holes.

The different die holes are suitable for different types of feed ingredients or different feed formulations. Generally speaking, the straight holes and the released stepped holes are suitable for processing compound feeds; the external conical hole is suitable for processing high fiber feeds such as skimmed bran; the internal conical hole and the compressed stepped hole are suitable for processing feeds with lighter specific gravity such as grass and meal.

The ring die compression ratio is the ratio between the effective length of the ring die hole and the minimum diameter of the ring die hole, which is an indicator of the extrusion strength of the pellet feed. The larger the compression ratio, the stronger the extruded pellet feed.

Due to the different formulas, raw materials, and pelleting processes, the selection of a specific and suitable compression ratio depends on the situation.

The following is a general range of compression ratios for different feeds:

Common livestock feeds: 1: 8 to 13; fish feeds: 1: 12 to 16; shrimp feeds: 1: 20 to 25; heat-sensitive feeds: 1: 5 to 8.