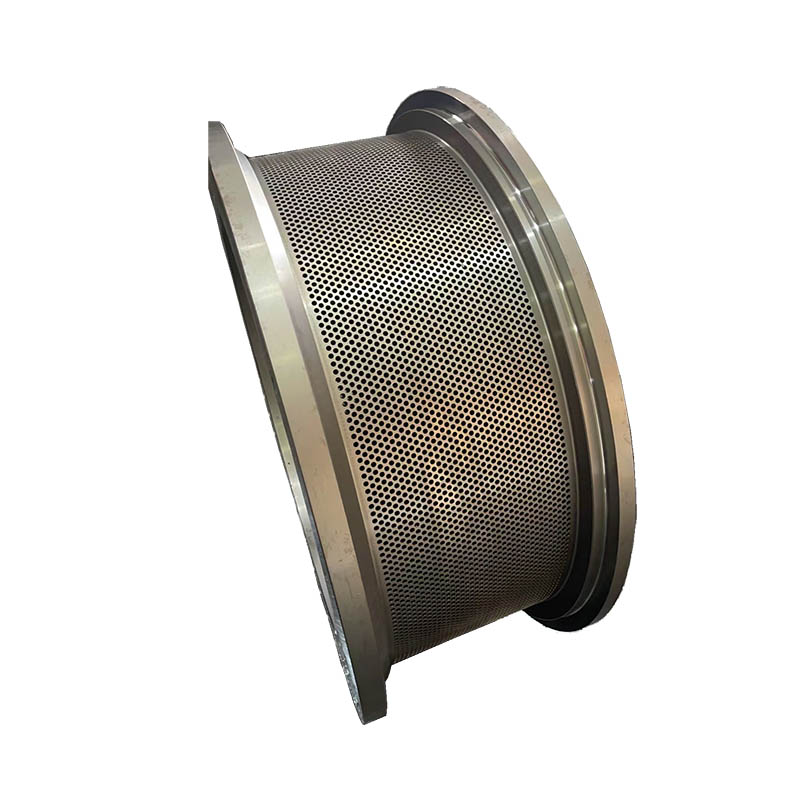

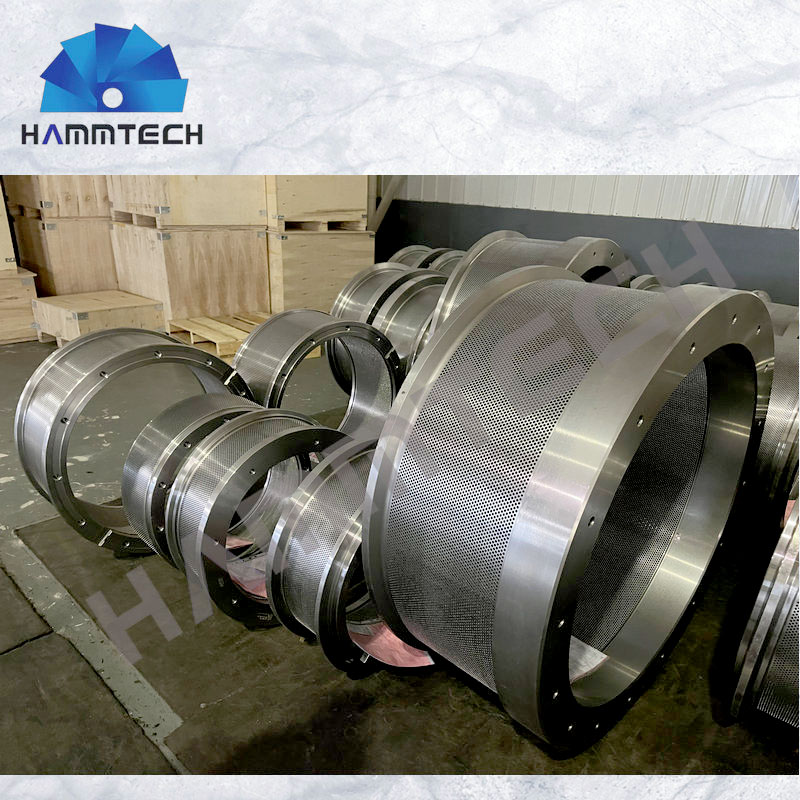

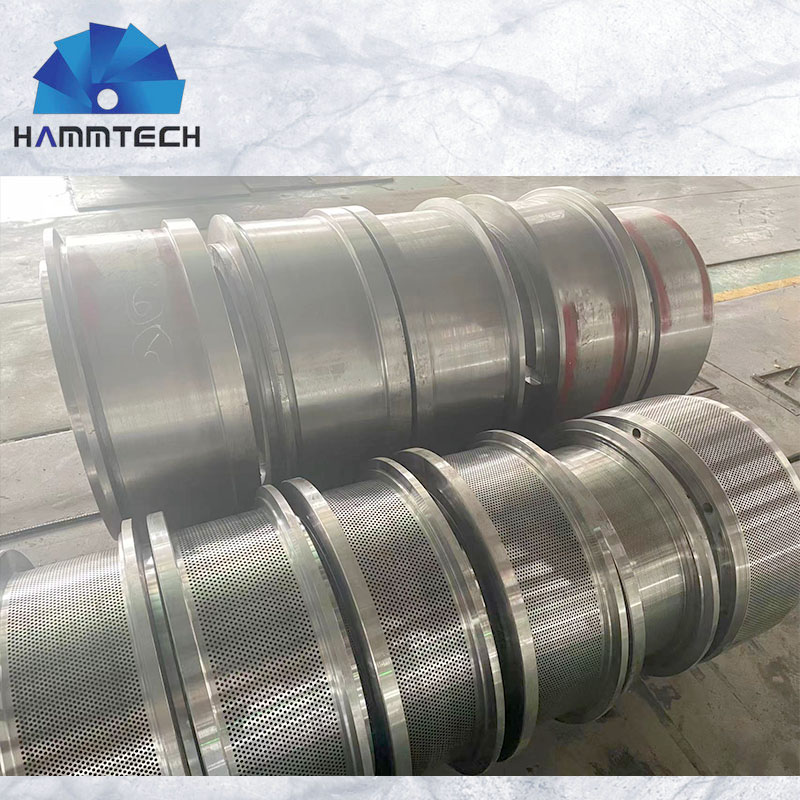

Biomass and Fertilizer Pellet Mill Ring Die

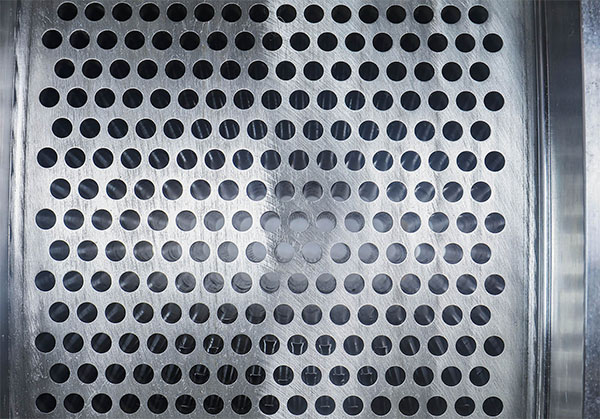

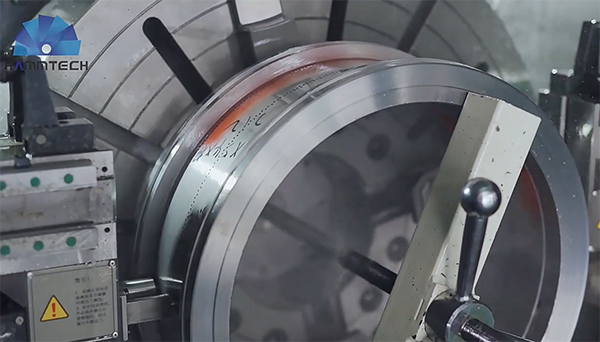

Our biomass and fertilizer pellet mill ring dies are made of high-quality alloy steel or high-chromium stainless steel. They are processed by forging, turning, drilling, grinding, heat treatment, and other processes. Through strict production management and quality control system, the hardness, die hole uniformity and die hole finish of the manufactured ring dies are of high quality. We not only improve the service life of the ring die, but also improve the appearance and texture of the extruded pellets, resulting in a smooth surface, uniform pellets and a small feed crushing rate.

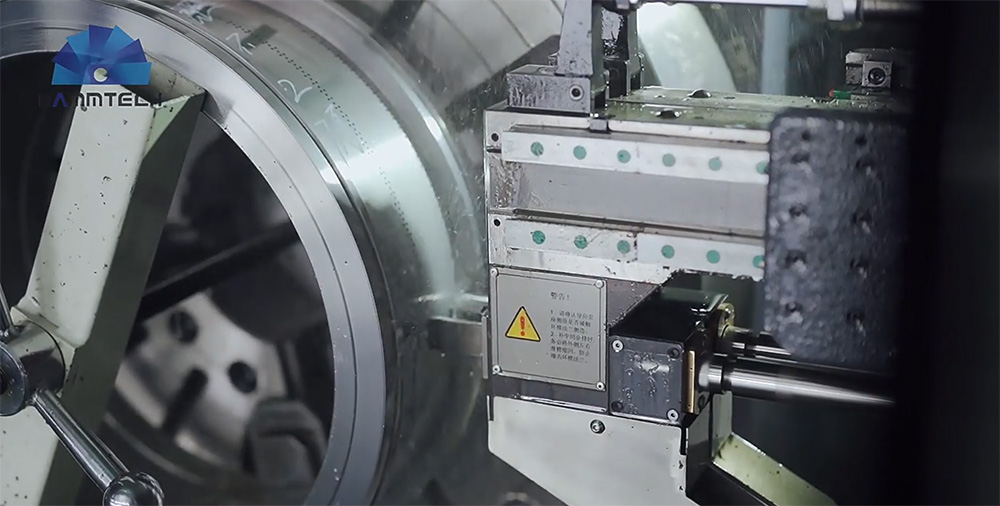

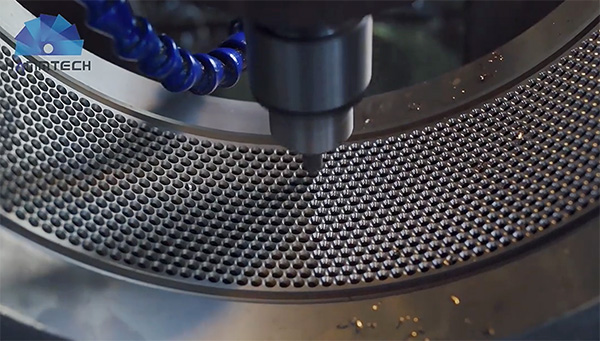

Advanced German gun drilling equipment, tools and drilling software are used in the machining of the die holes.

The die holes are positioned with high precision.

High rotational speed, imported tools and coolant ensure the required process conditions for drilling.

The roughness of the processed die hole is small, which ensures the pelletizing output and quality.

The quality and service life of the dies are guaranteed.

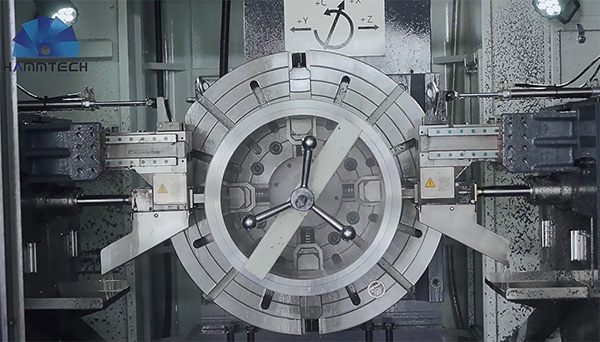

Raw material forging — Rough turning — Half-finished turning — Drilling the hole — Grinding inner bore

Treaded hole — Keyway milling — Heat treatment — Finish turning — Packaging & delivery

How to maintain and inspect the ring die?

A. The rollers should be correctly adjusted, make sure the hole inlets are not damaged by contact with the rollers or as a result of tramp metal.

B. Material should be evenly distributed across the whole working area.

C. Make sure that all holes work uniformly, opening the clogged holes if necessary.

D. When changing dies, carefully inspect the condition of the die seating surfaces and fixing systems including collar, clamp or wear ring.