Application Particles of Tungsten Carbide Welding Technology in Shear Vulnerable Parts

1. Dual wear resistance: The surface is made of German wear-resistant welding material; The second layer is YG8 particles of tungsten carbide.

2. Super impact resistance: The surface is made of wear-resistant welding materials welded onto particles of tungsten carbide, with a rough welding surface and better biting force; The secondary layer is composed of particles of tungsten carbide dissolved and welded on the surface of the substrate, without cracks or peeling, forming a whole.

3. Sharp edge cuts for better cutting effect

4. During use, particles of tungsten carbide with sharp edges can have a secondary tearing effect, resulting in better tearing effect.

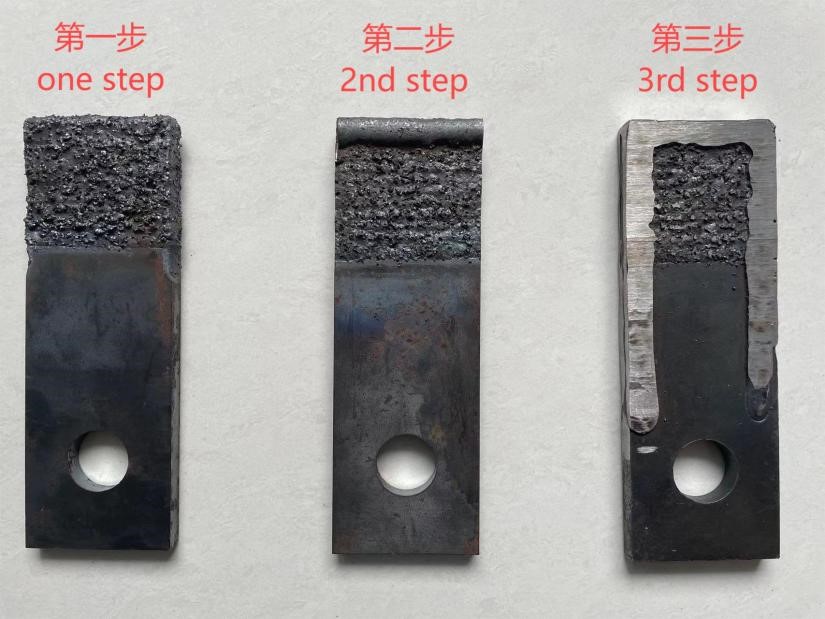

1. particles of tungsten carbide welding process, which combines particles of tungsten carbide with substrate to form a tungsten carbide wear-resistant layer.

2. Perform secondary welding on the surface of the wear-resistant’s tungsten carbide and weld it with German wear-resistant welding rods. Because the surface of the wear-resistant’s tungsten carbide is covered with many particles of tungsten carbide, the rough welding surface provides better biting force.

3. After the wear-resistant welding rod is welded, it should be polished to form a sharp cutting edge. The finished hammer blade of tungsten carbide not only maintains the wear resistance and impact resistance, but also has the ability to cut and tear twice.

Specially recommended products for use.