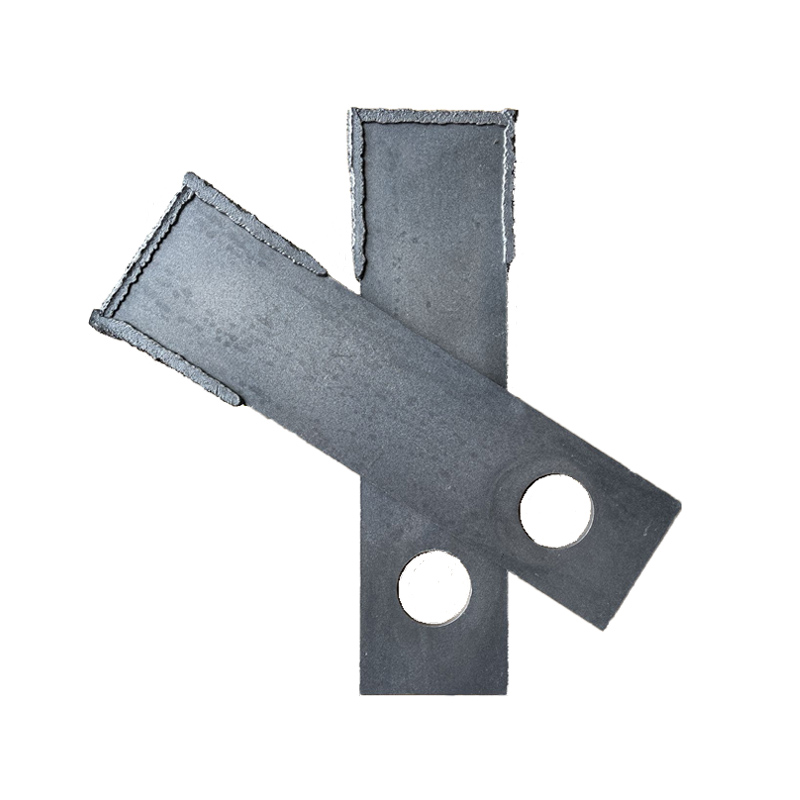

3MM Hammer Blade

Hammer blade is the most important and most easily worn working parts of the crusher. Its shape, size, arrangement method, and manufacturing quality have a great impact on the crushing efficiency and product quality.

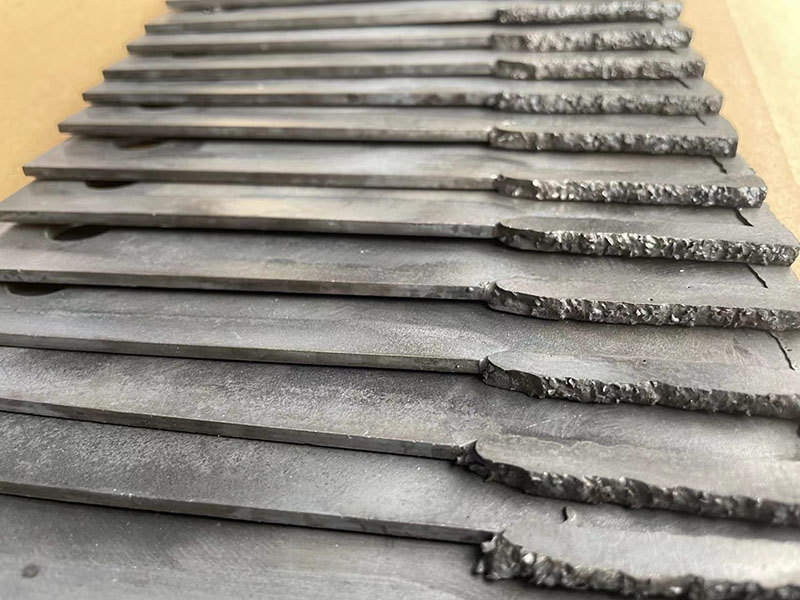

There are many shapes of hammer blades currently in use, but the most widely used is the plate rectangular hammer blade, as it is simple in shape, easy to manufacture and has good versatility. It has two pins on it, one of which has a hole strung on the pin, and can be rotated to work using the four corners. The working side is coated and overlaid with tungsten carbide or welded with a special wear-resistant alloy to extend the service life, but the manufacturing cost is higher making the four corners trapezoidal, angular and sharp to improve its crushing effect on forage fibre feed, but the wear resistance is poor.

The annular hammer blade has only one pin hole and automatically changes its working angle during work, so it wears evenly and has a long service life, but the structure is complex. Composite steel rectangular hammer blade is provided by the rolling mill two surface hardness of the middle layer of good toughness of the steel plate, the manufacture of simple, low cost.

We can provide complete sets of accessories, including hammermill hammer blade, granulator ring die parts, flat die parts, granulator grinding plate, granulator roller shell, gear (large/small), bearing, connecting hollow shaft, safety pin assembly, coupling, gear shaft, roller shell, roller shell assembly, various cutters, and various scrapers.